Precast Concrete Wall Lifters: Design Guide from PMtech Engineering

Precast Concrete Wall Lifters Guide

The article provides guidance on the detailing of lifters for precast concrete walls.

Three main groups of lifters are discussed: threaded lifting systems, flat lifters, and slot lifters, each with their own characteristics and considerations.

Placement of lifters is then addressed, emphasizing the ideal symmetric placement related to the center of gravity.

The article also discusses additional reinforcement requirements around lifters to accommodate out-of-plane forces and ensure structural integrity during production and transportation.

Overall, the article provides a thorough overview of the considerations and best practices for detailing lifters for precast concrete walls, covering aspects from system selection to placement and additional reinforcement requirements.

1. The importance of the entire production and installation workflow

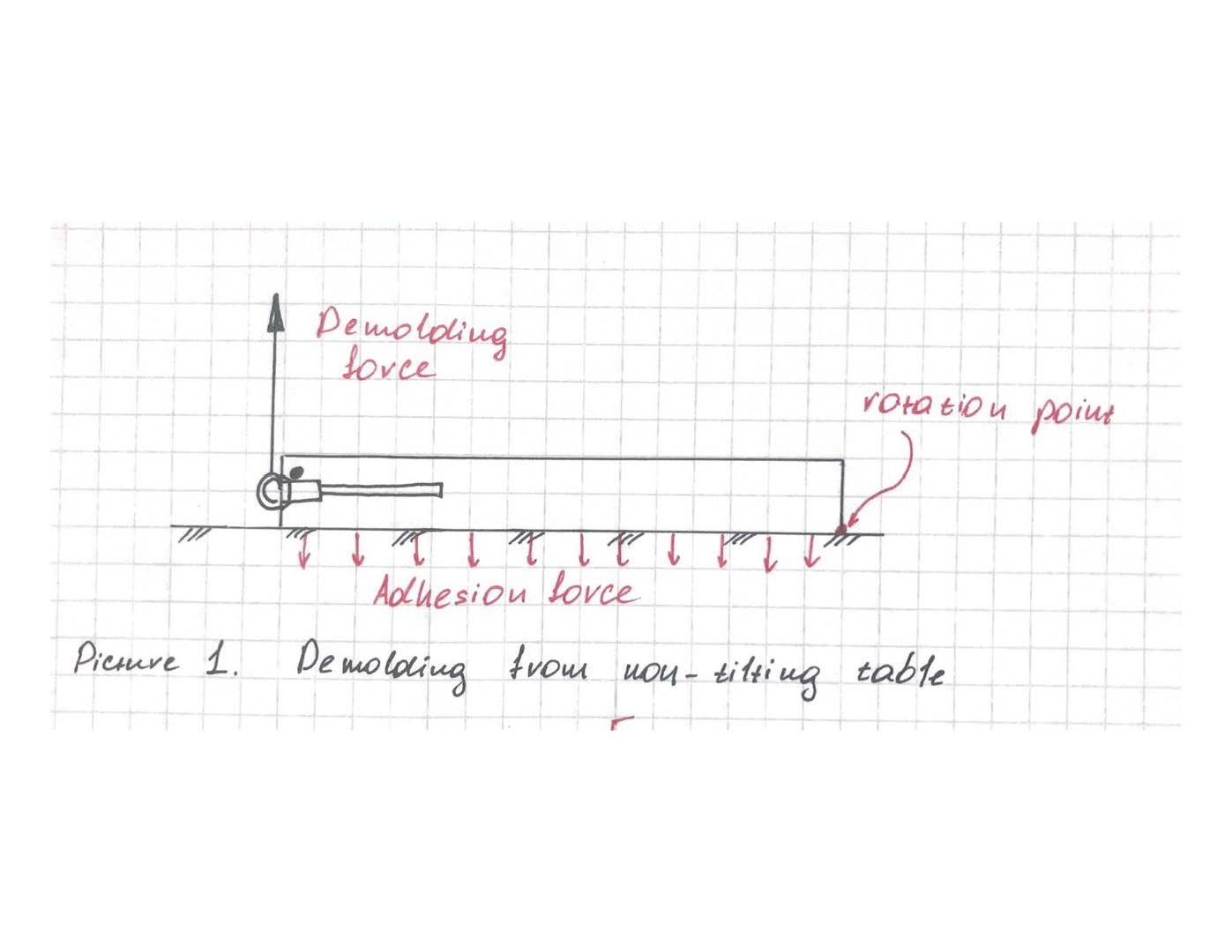

First it is necessary to be aware of the whole workflow from production to installation. The wall can be produced on a tilting or non-tilting table at the factory. If the non-tilting table is the case, additional out-of-plane forces during demolding must be taken into account as well as a possible mould adhesion (picture 1).

Further, it is necessary to know which lifting devices are available at the factory and site, what is the allowable lifting sling height. The last is especially relevant for “low” production lines where the distance between the wall’s top and the crane is limited. Traverse allows decreasing the sling height.

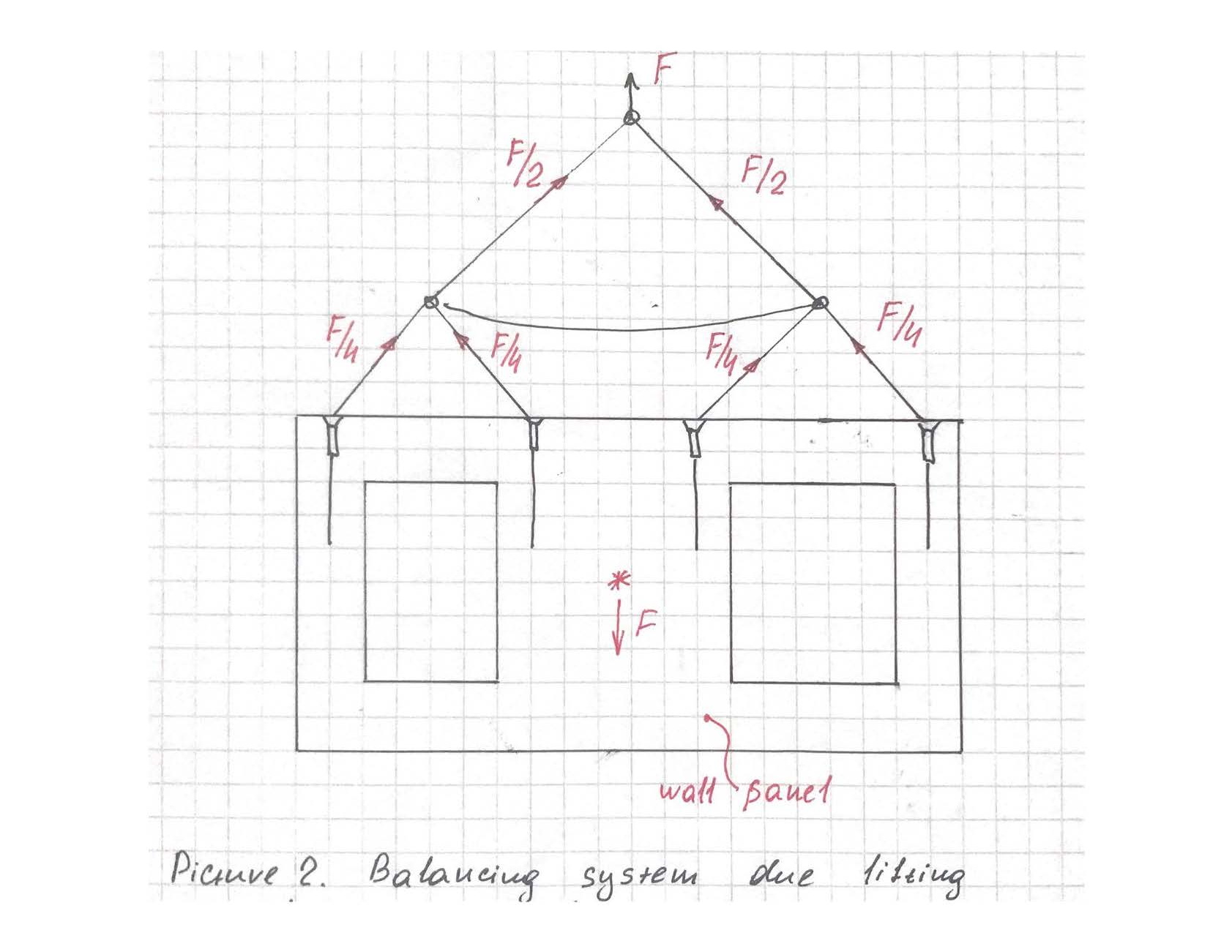

Employing balancing devices is also beneficial, as they enable the sling system to be treated as statically determined, thus facilitating the effective use of 3- and 4-lifter systems. (picture 2)

It is important that factory and installation teams follow the designed lifting workflow: from production to final installation.

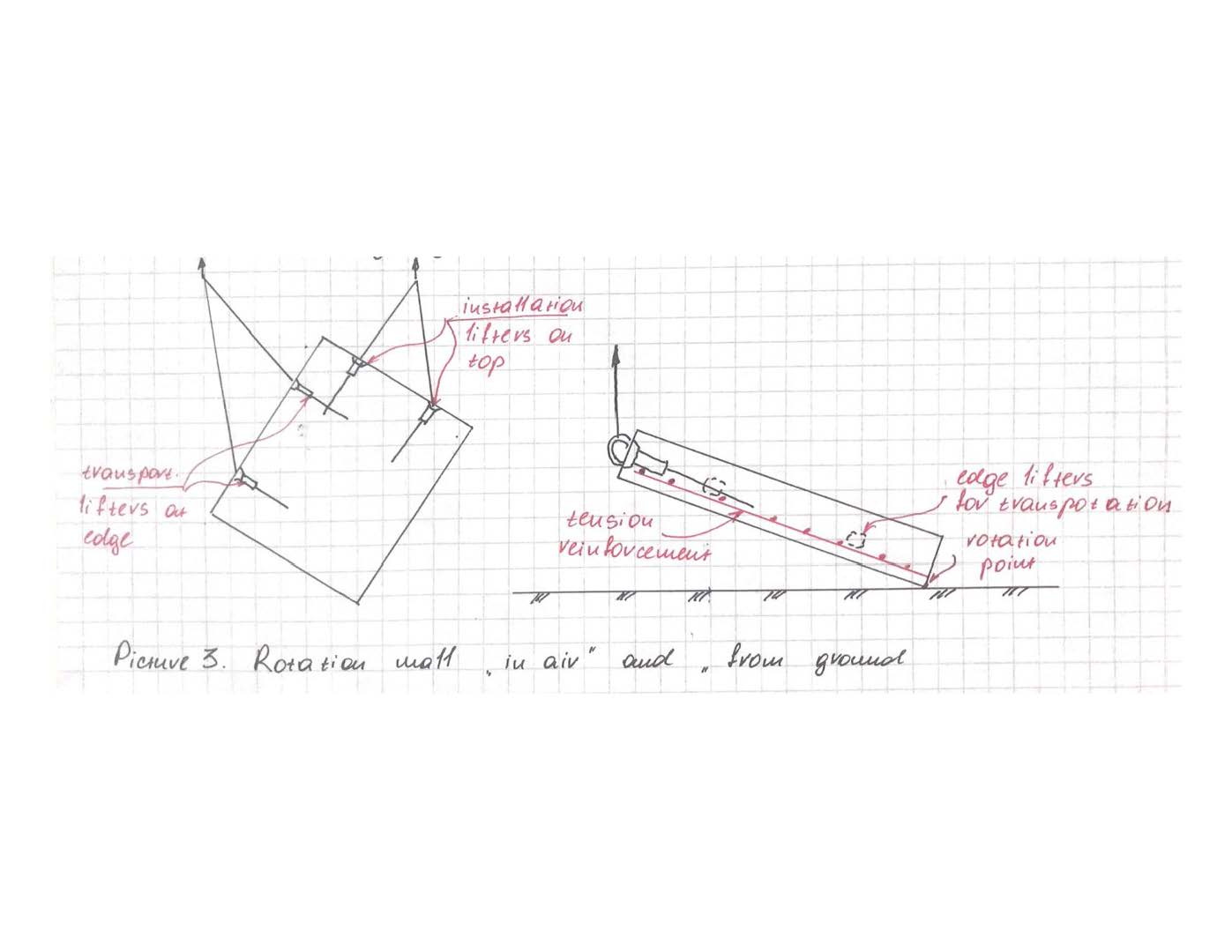

Sometimes separate sets of lifters are designed for demolding/transportation and installation. It is important to show the lifting/demolding strategy in the production drawings. In some cases wall must be rotated “in air” or “from ground” for installation (picture 3). The last options requires an additional reinforcement check as during rotation wall acts as a slab.

2. Choice of the lifter system.

To choose the lifter system it is necessary to consider:

- Allowable lifting devices at factory and site;

- The cost and availability on market;

- Capacity. Lifter suppliers provide guidance on how to choose their products related capacity;

- Detailing aspects.

This article describes the detailing aspects.

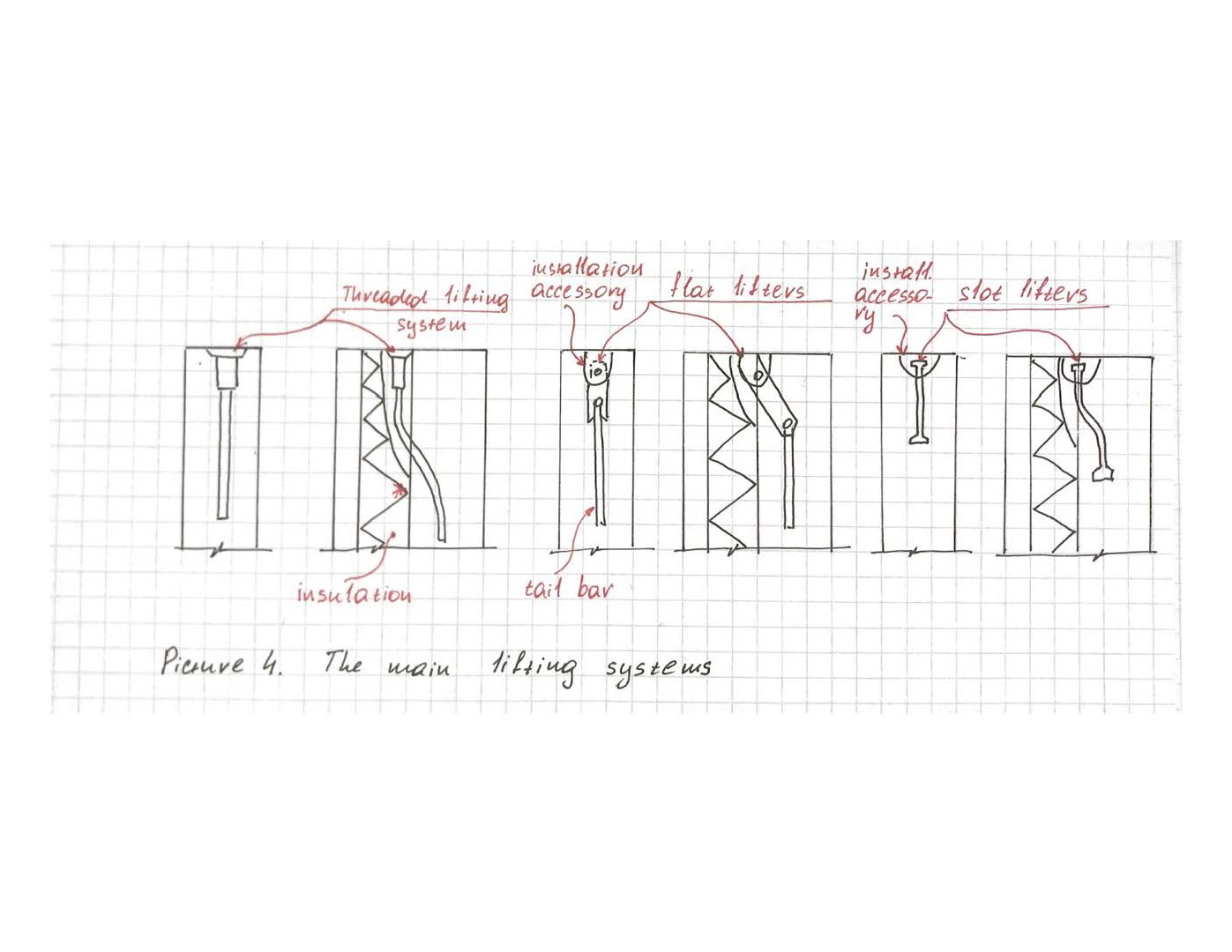

Suppliers provide a wide range of the lifters for the precast wall. The most common the next 3 groups:

- threaded lifting system;

- flat lifters;

- slot lifters.

Additionally, each groups contains separate lifters for 3-layer sandwich walls (picture 4). Those lifters are bent to place lifting key closer to center of gravity. In 3-layer sandwich walls center of gravity is usually near the border between insulation and structural layer.

Comparison of lifting systems from the detailing point of view:

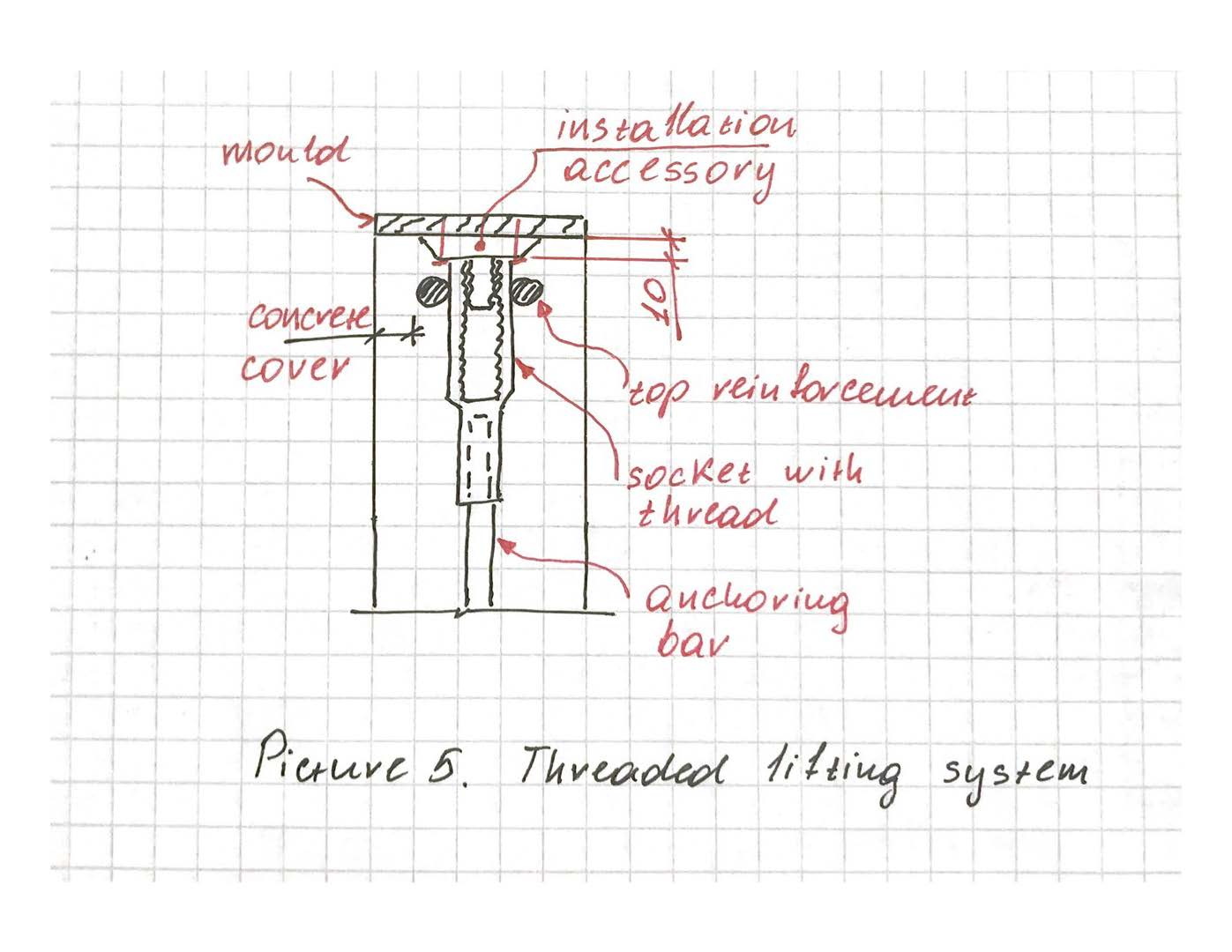

threaded lifting system:

– have a compact geometry. It makes easier to place them between the wall reinforcement;

– not required a long “tail” bar;

– has small size for the given capacity – this gives more freedom for the wall reinforcement, especially it is important for the thin 160-200mm walls.

– compact installation accessory. (picture 5)

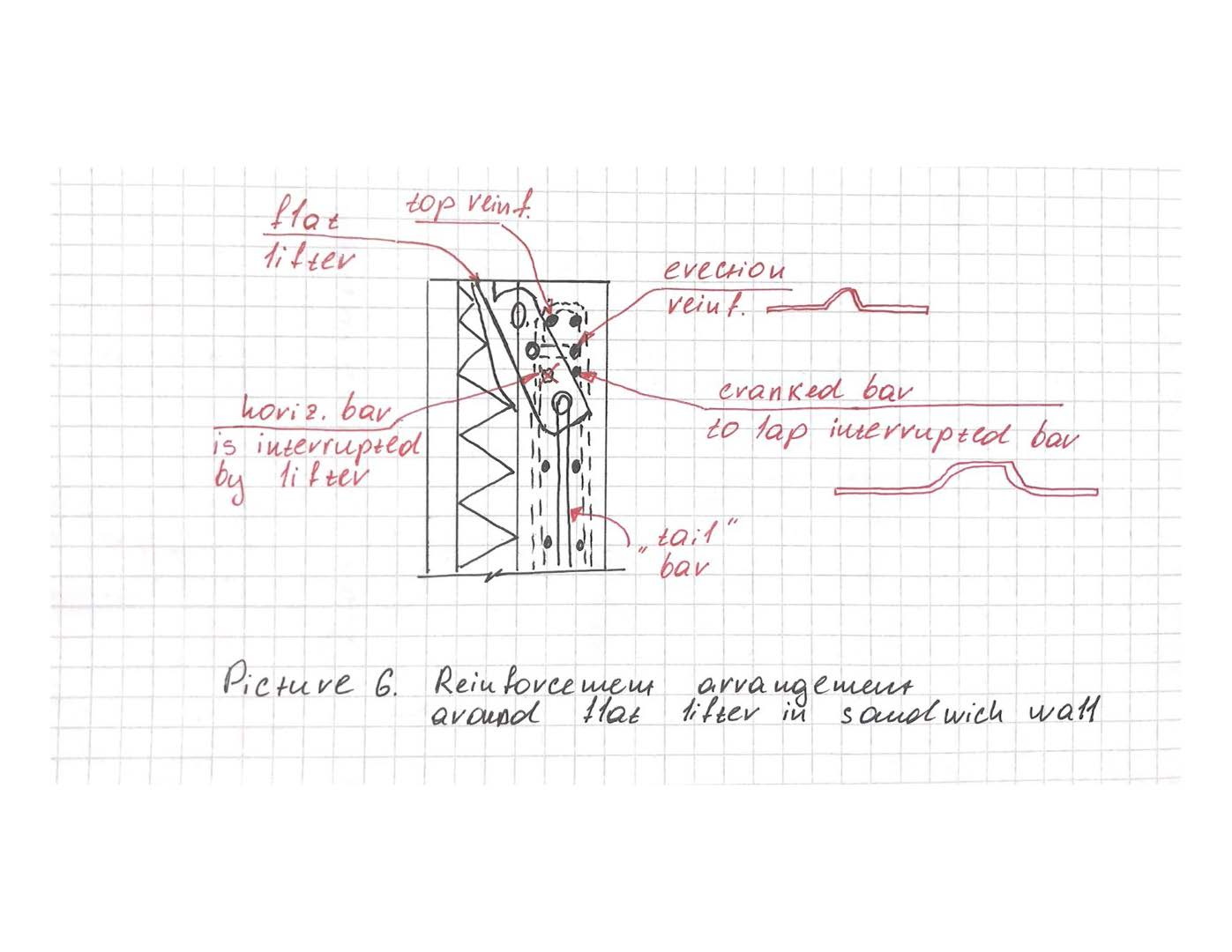

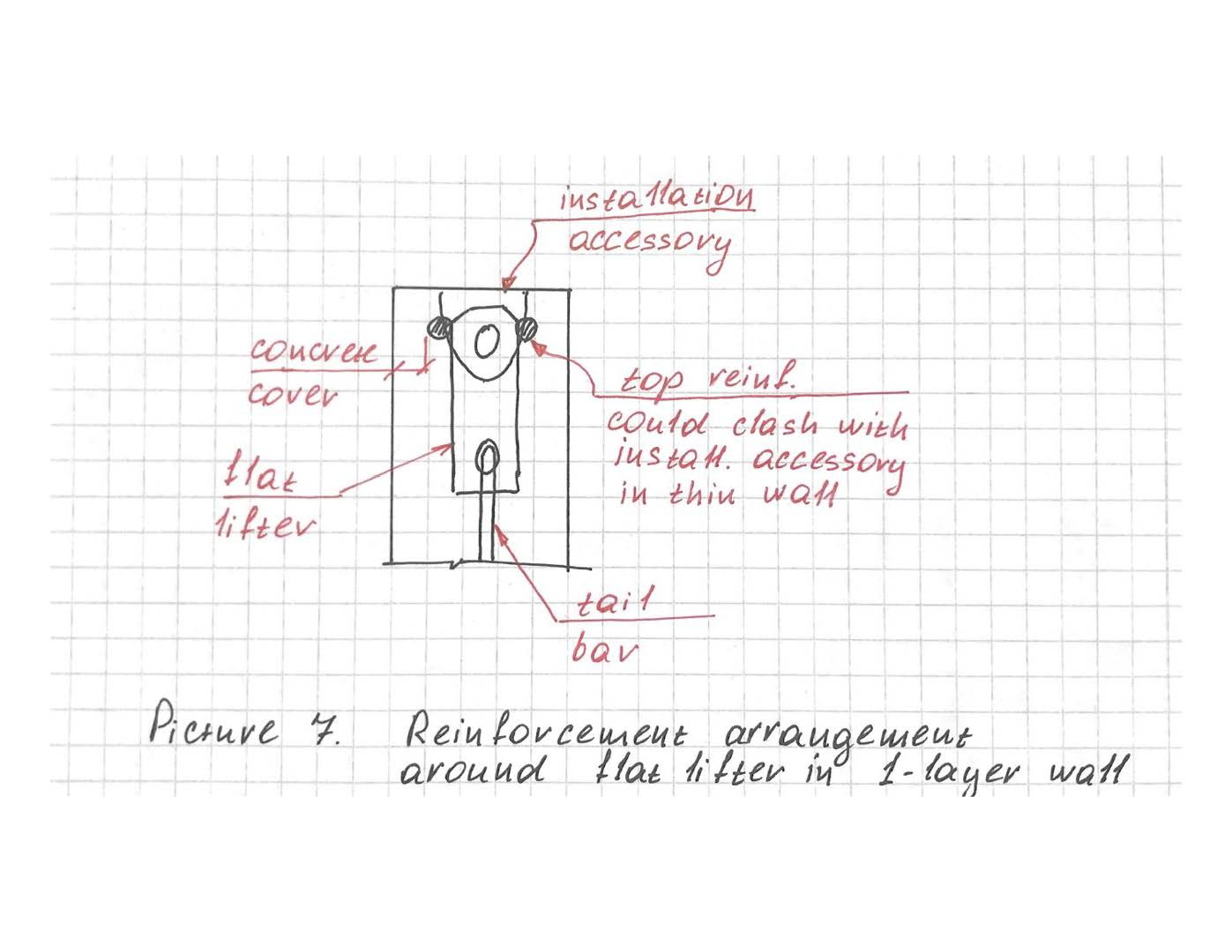

flat lifters:

– require a long “tail” bar;

– In 3-layer sandwich wall inclined flat lifter clash reinforcement closer to insulation layer, so additional cranked bars are required to provide continuous reinforcement (picture 6);

– require large installation accessory, which could clash with the wall top reinforcement (picture 7).

slot lifters

– have compact geometry. It makes them easier to place between the wall reinforcement;

– not required a long “tail” bar;

– require spherical installation accessory, which could clash with the wall top reinforcement.

3. The placement of lifters.

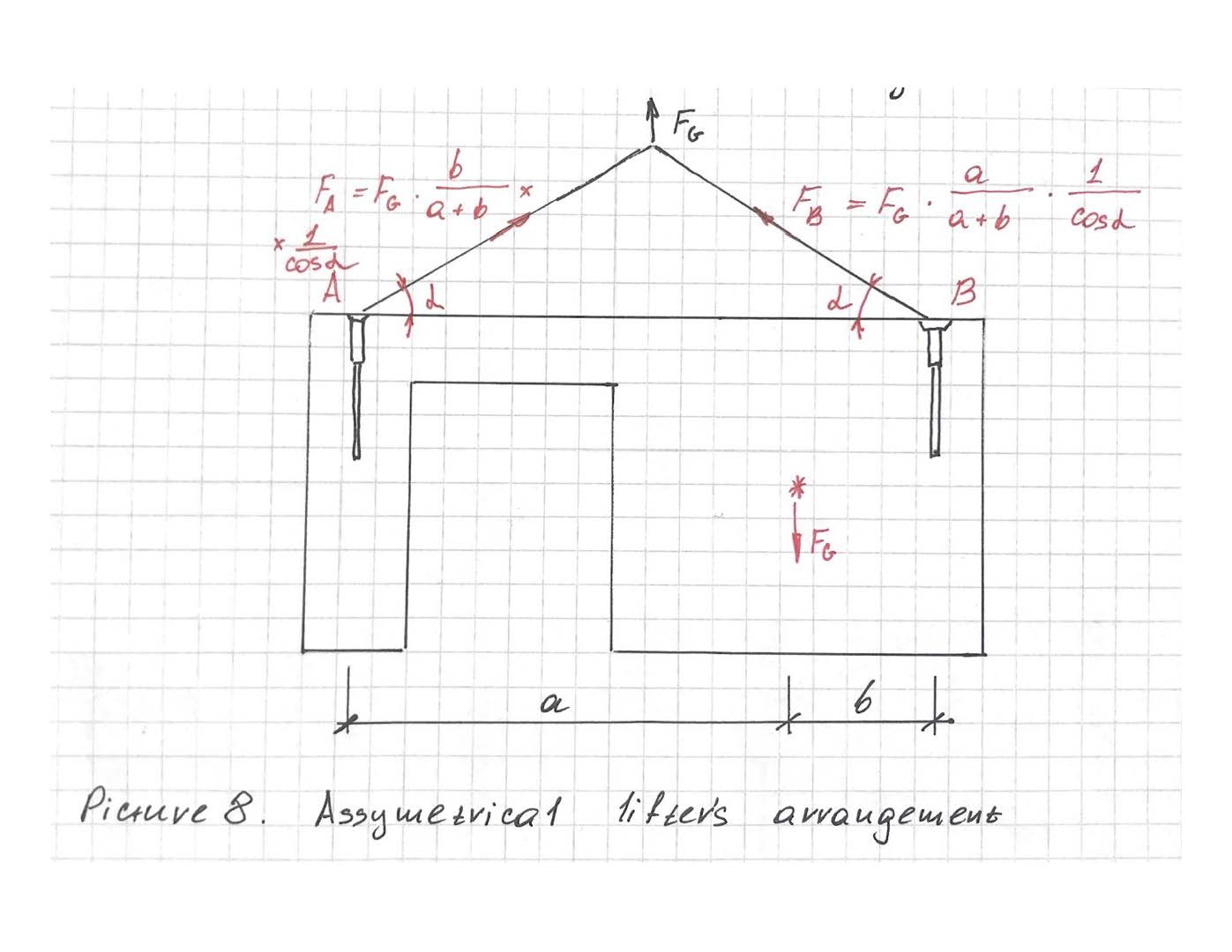

The best way is to place lifters symmetrically related to centre of gravity in both directions: “on wall elevation” and “perpendicular through wall”. However, in reality there are a lot of reasons and obstacles, which do not allow doing so. (picture 8)

If lifters are asymmetrical related to center of gravity “on wall elevation” it means that one lifters is more loaded. In such a case a consideration about required lifter capacity must be done. It is not practical to place different lifters in one wall, so lifters are applied according to the biggest one.

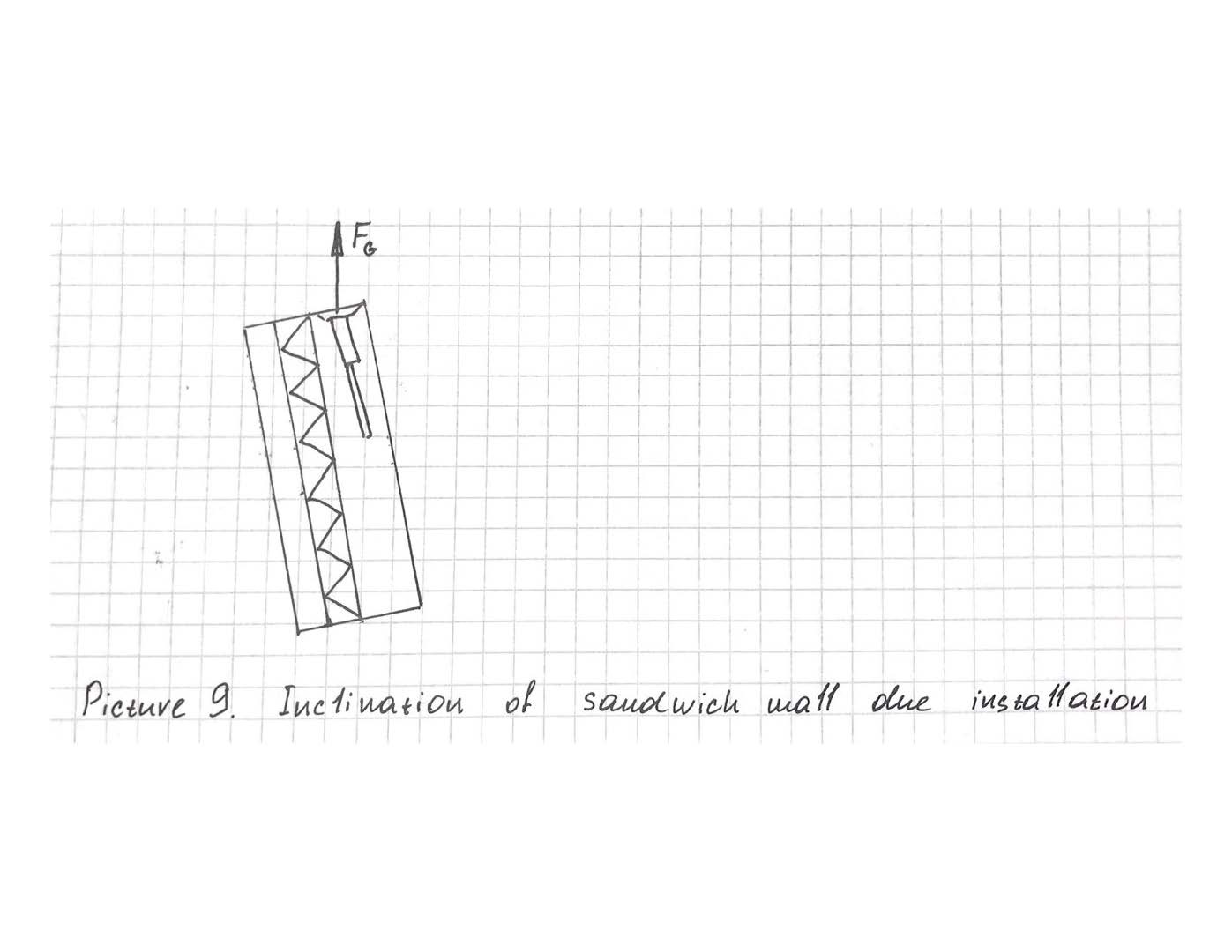

If lifters are asymmetrical related to center of gravity “perpendicular through wall” it lead for inclination of wall during the installation. Such inclination must be avoided using special lifters for 3-layer walls or additional balancing lifters in the external leaf. This issue is mostly common for the 3-layer sandwich walls and asymmetrical 1-layer walls. (picture 9)

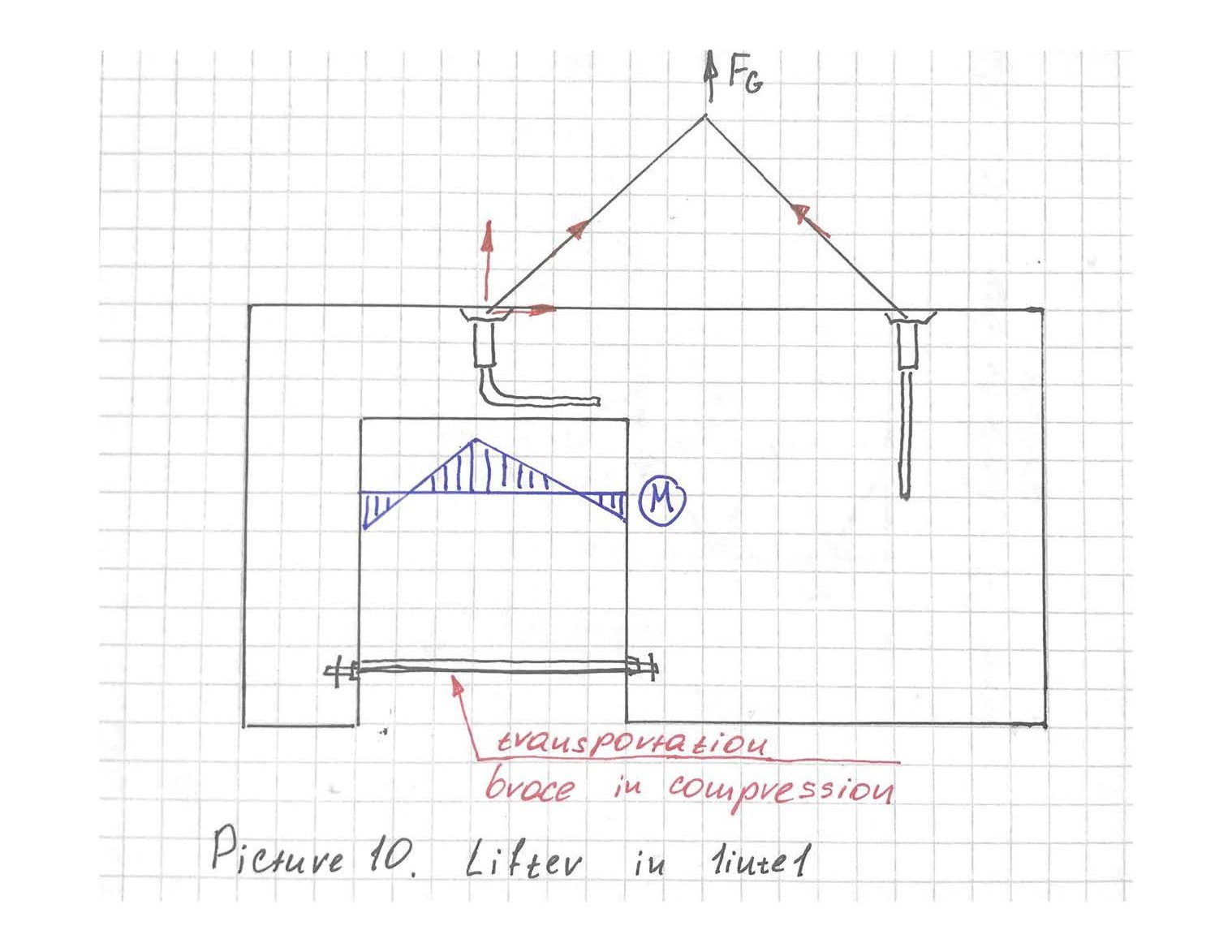

It is desirable to avoid placement of lifters in lintels above openings. If it is not possible to avoid this, the linters must be checked for transportation design situation (picture 10). In addition, there could be additional issues to place heavy lifters in the narrow lintel.

Placement of lifters affects on temporary transportation braces in door openings. Depending on the lifter’s arrangement braces can be in tension or compression.

4. Additional reinforcement.

Here is the main points.

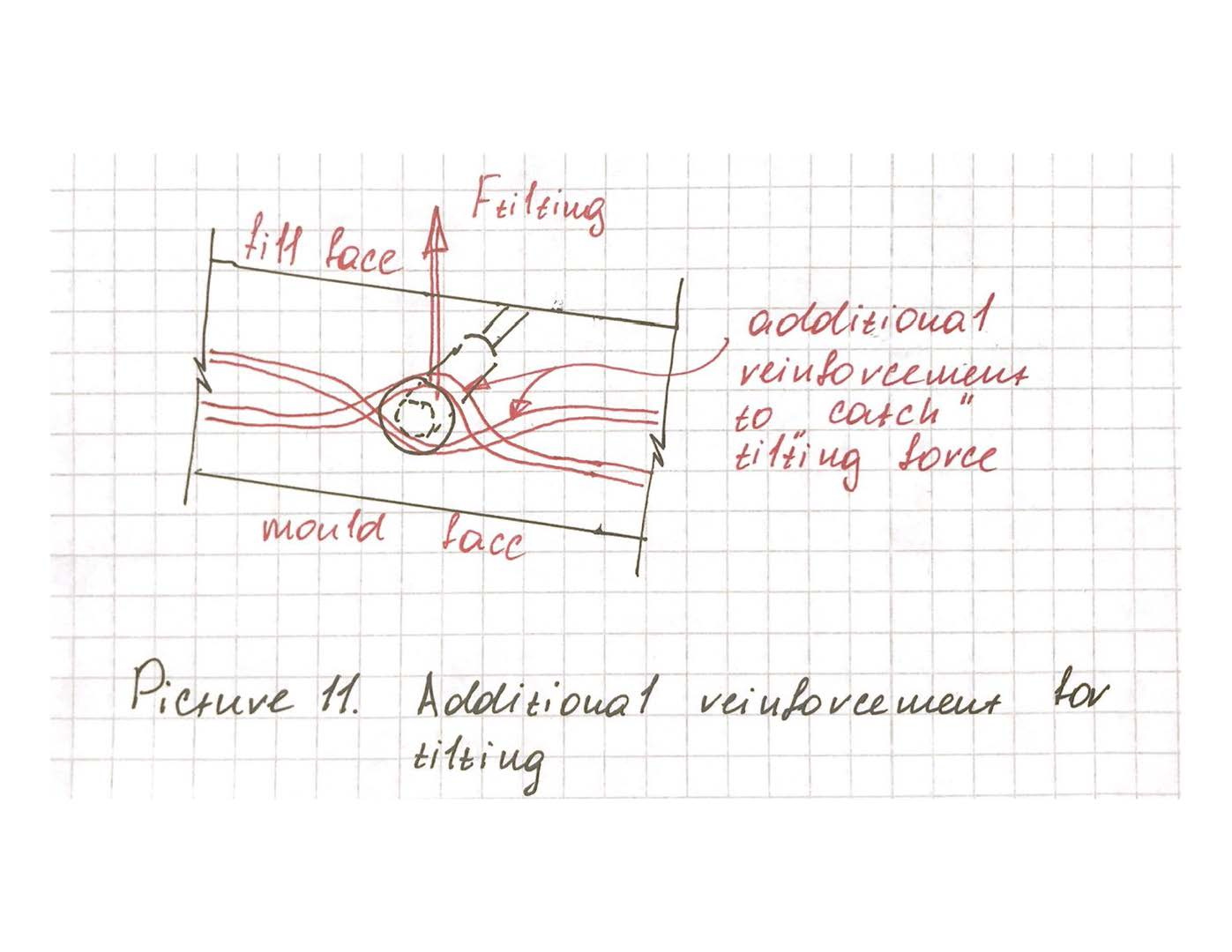

If the lifters are assumed to take out-of-plane forces at any stage of production or transportation, it is necessary to place additional reinforcement to “catch” those forces. (picture 11)

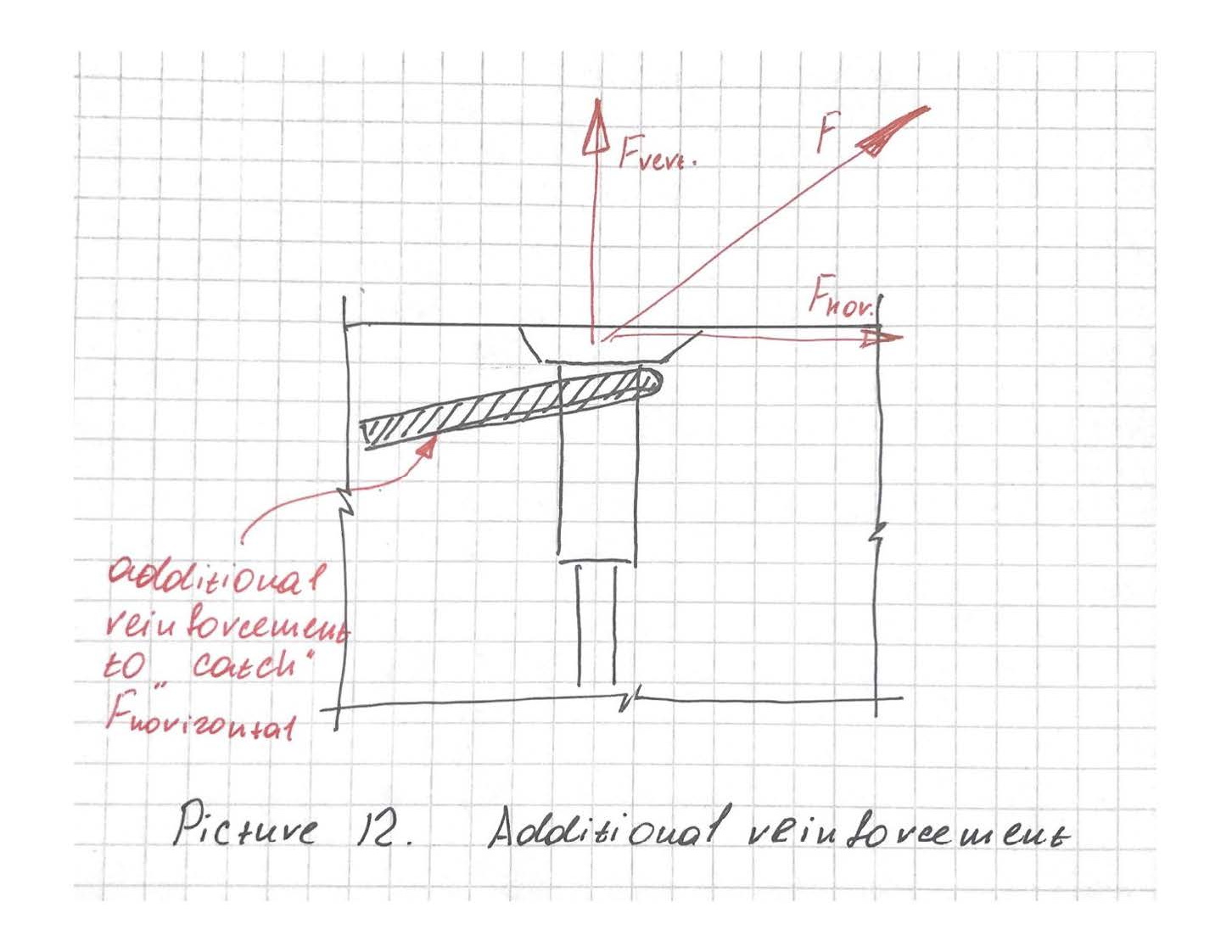

Inclined U-shape bars “catch” in-plane force from lifting sling. (picture 12)

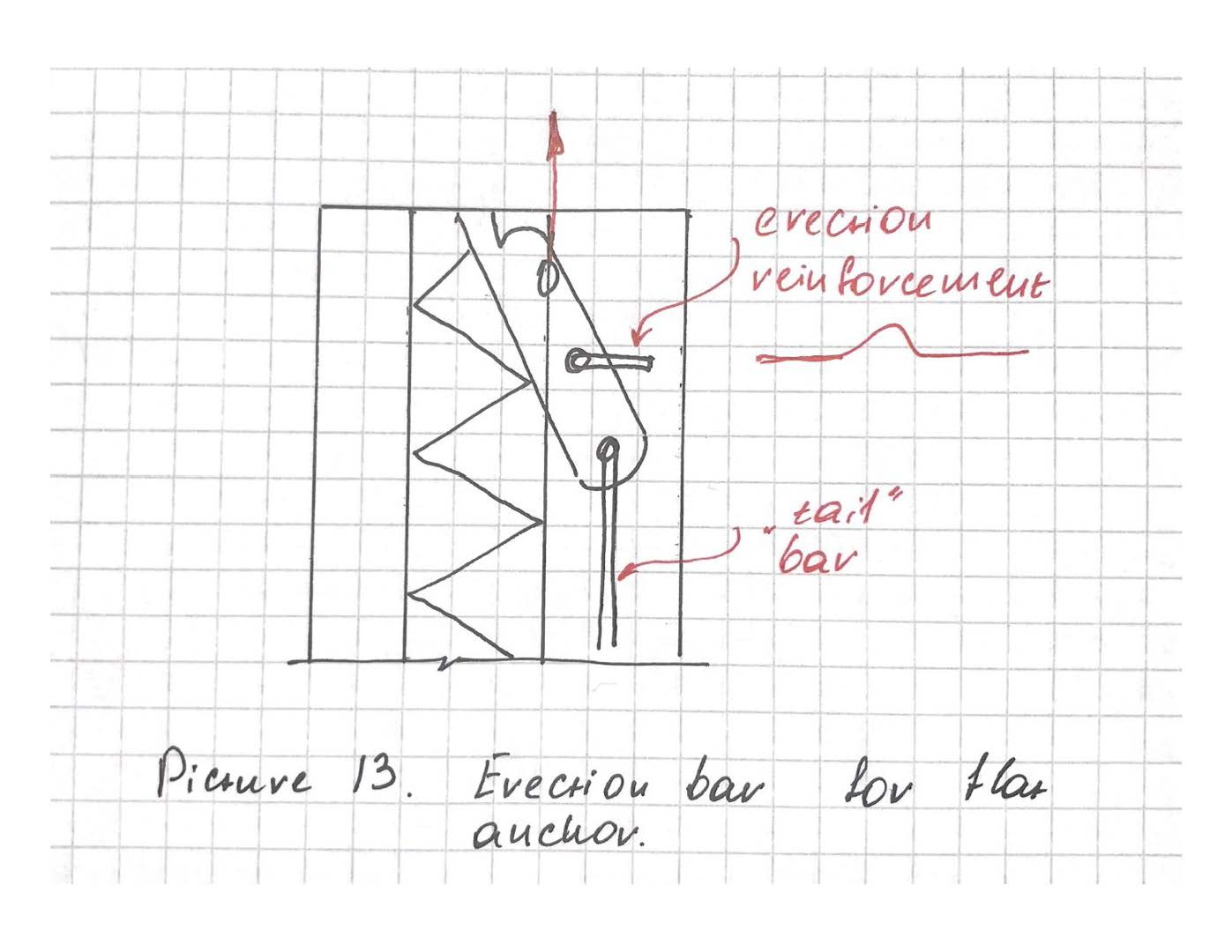

Flat lifters transfer the vertical load through “tail” bar.

Flat anchors for 3-layer sandwich walls require an additional erection bar. (picture 13)

Additionally there are requirements about the min. wall reinforcements, top U-bars, longitudinal bars along the edge described in the supplier’s guidances.