Commercial building

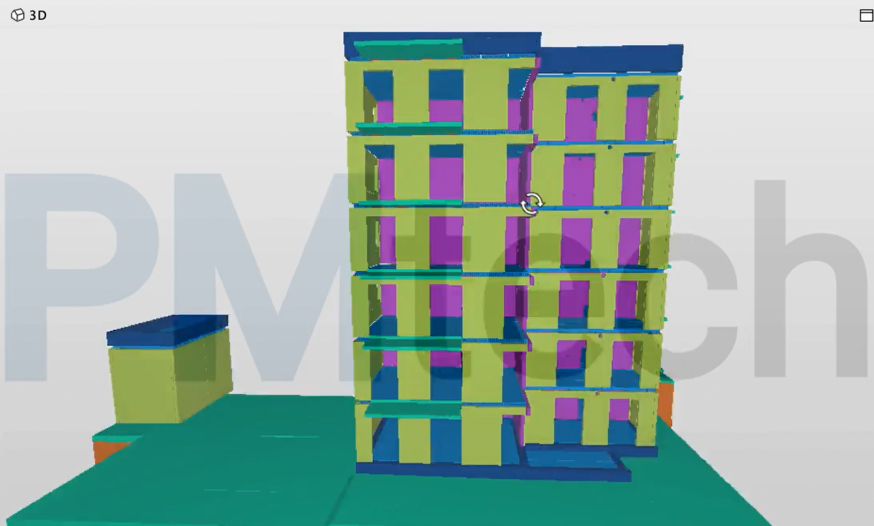

Residential 4-Story building with attic, Spain

SOFTWARE PRODUCTS: AUTODESK REVIT, BIM360, 3D MAX Render

PROJECT INFORMATION

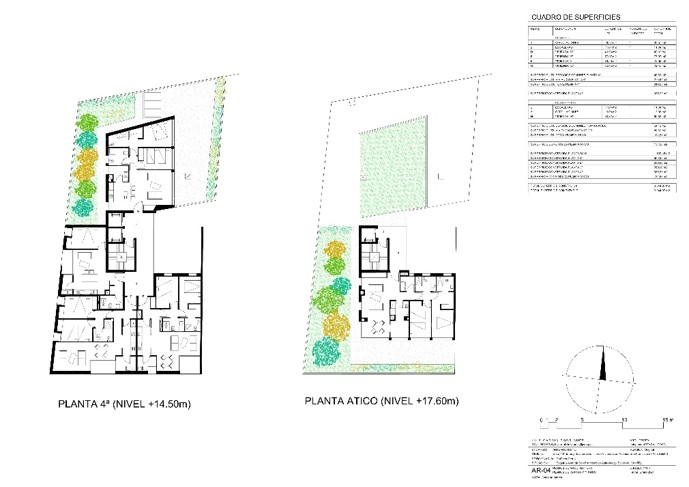

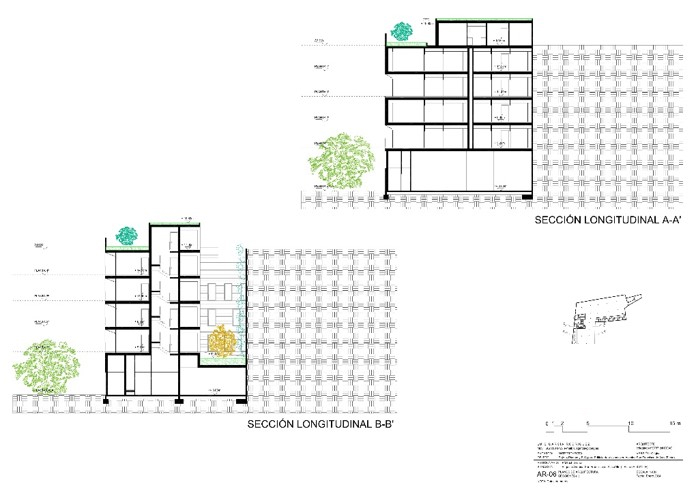

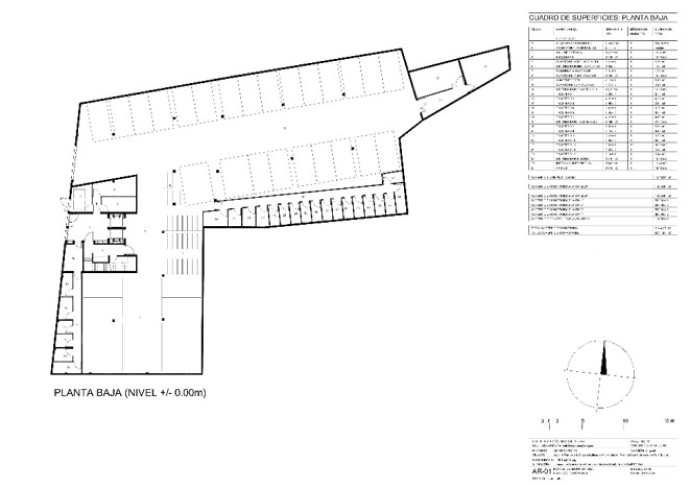

Scope of work: The residential building is located in the province of Alicante, Spain. The building has a basement, four floors above ground and an attic.

Localization and Context:

The land plot, formed by the merging of several parcels, is located in a developed urban area. Shaped like an “L,” it spans 1 593 m². The building’s design aligns seamlessly with the surrounding architecture.

Concept and architectural solution:

The building incorporates reinforced facades, along with interior walls and partitions constructed from gypsum blocks and advanced drywall systems, providing enhanced acoustic insulation and protection from external environmental factors.

Windows and Doors: Made of aluminum profiles with thermal breaks, providing high thermal insulation. Multi-layered double-glazed windows with low-emission coating enhance the building’s energy efficiency.

Inner Courtyards and Covered Terraces: Designed to maximize natural light and ventilation, the development features integrated courtyards and covered terraces. These spaces include dedicated areas for children’s play and sports activities, as well as recreational zones, with pathways illuminated by energy-efficient LED lighting systems.

Color Scheme: White porcelain stoneware facades with dark-colored frames and exterior elements that are durable and resistant to external factors.

Green Areas: 40% of the territory will be landscaped. Rainwater collection tanks will be installed.

Engineering systems: Central heating, air conditioning, water supply system, sewage, and electrical networks comply with energy efficiency standards. The security system includes video surveillance, security post, access control using smart cards and biometric data.

PROJECT DESCRIPTION

Architectural Solutions:

Basement: Area of 1120.46 m², including 32 parking spaces (including spaces for people with disabilities), bicycle stands, storage rooms, and technical premises.

Solar Panels: Solar panels will be installed on the roof to provide a hot water supply and partial power supply for common areas.

Water Conservation: Systems for collecting and using rainwater for irrigation of green areas and toilets in common areas to reduce water consumption.

Use of Renewable Energy Sources: The potential for installing heat pumps to provide heating and air conditioning using renewable energy.

The project integrates modern energy-efficient and ecological solutions, such as vertical gardens and green roofs, aligning with contemporary trends in sustainable development in architecture.

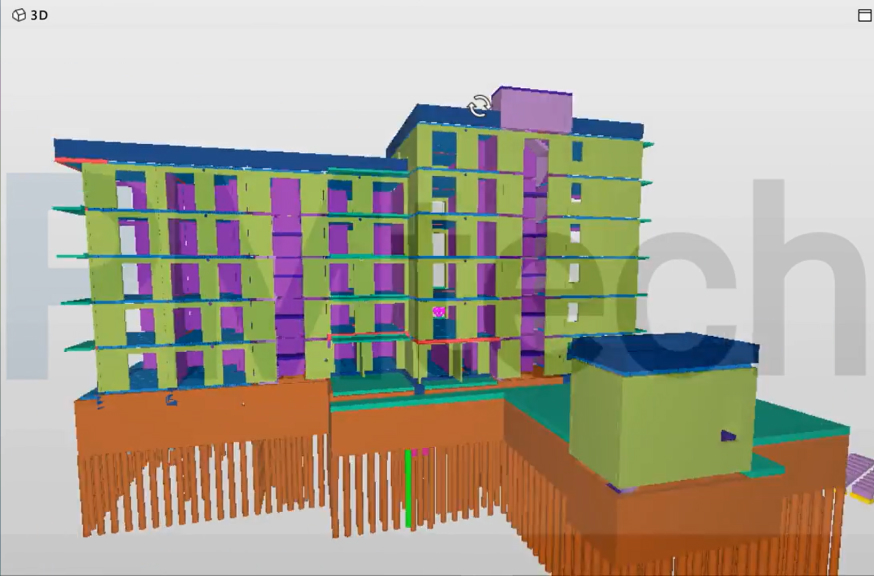

Residential building. Full cycle of structural design

SOFTWARE PRODUCTS: TEKLA STRUCTURES, DLUBAL RFEM

PROJECT INFORMATION

PMtech Group Engineering provides the full cycle of structural project design, including

– Tender project preparation

– Project management

– Structural calculations

– Structural detailing (engineering, fabrication and construction)

– Preparation of drawings

We use Tekla Structures, Autodesk Revit, Advance Steel software for detailing and drawings, and Tekla Model Sharing or BIM360 technology for coordination, so that the client can see progress at any time and overlook the model if they wish.

PROJECT DESCRIPTION

Calculations and design are performed according to Eurocodes parts and relevant EU National Annexes and UK National Annex. Dlubal RFEM and IDEA Statica software are used for calculations.

We have over 5 years and more than 40 completed projects in the European Union, the UK and design experience in precast concrete, in-situ concrete, steel structures, mixed structures (concrete-steel, concrete/steel-timber, etc.).

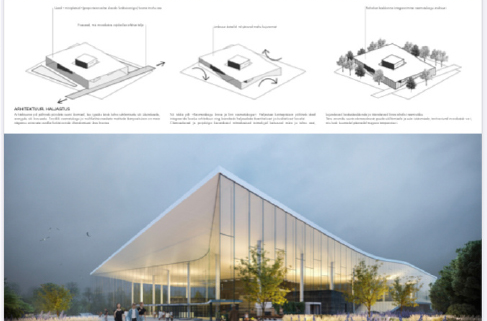

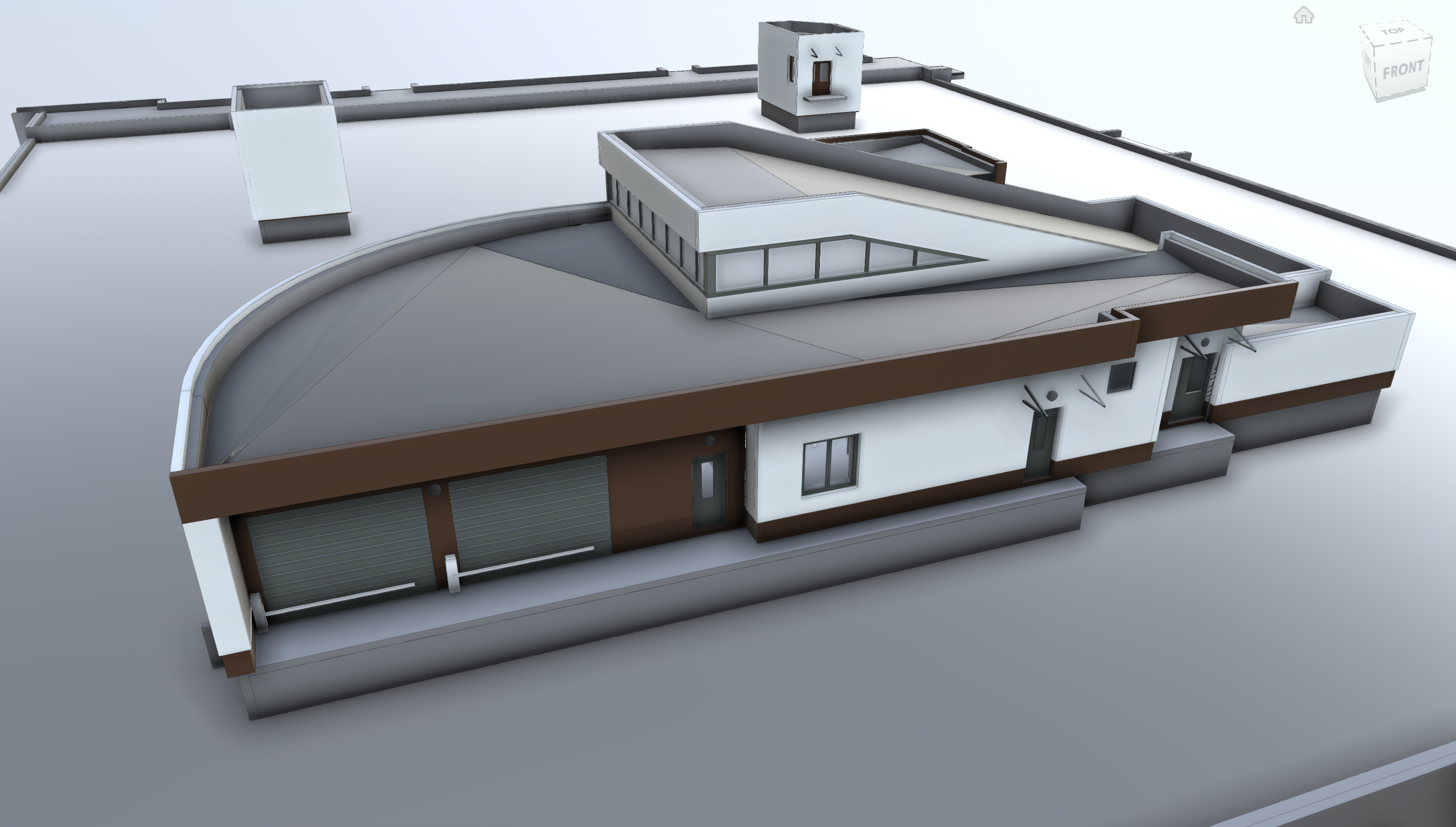

Public center in Tartu (Estonia): from the idea to the creation

SOFTWARE PRODUCTS: REVIT AUTODESK, 3D MAX, CIVIL 3D

PROJECT INFORMATION

“It all started with the idea of creating a space without boundaries, which wouldn’t be noticeable and active. Architecture wouldn’t dominate over people. A space where everyone could find their place. A place where they could develop, communicate, and create. A place that would naturally push people to explore the new and not be afraid to express the boldest ideas,” – shared one of the participants from the joint group with LEVEL80 | architects

The project idea for the architectural competition in Tartu was about creating a harmonious space without boundaries, where architecture serves people.

Experts from Level80 combined inner cubic structures and a light library shell, event centers, a unique space for museums, a cinema, and offices. The architects aimed to make the building appealing from all sides, using wood and minimizing concrete and steel.

PROJECT DESCRIPTION

An important part of our specialists’ work at PMtech Engineering was designing evacuation exits and ensuring the building’s safety. We contributed to creating parking lots and developing complex structures, including knee elements and spans. The experience and knowledge of engineers at PMtech Group allowed ensuring the building’s structural integrity and create a balanced and functional space.

This project provided us with a unique opportunity to demonstrate technical expertise and make adjustments to the architectural asset – the cultural center of Tartu (Estonia). We’ve analyzed the technical solutions proposed by the architects and provided consultation on structural design and energy efficiency of the future building

Specialists at PMtech Engineering integrated sustainable technologies and believe that such an approach ensures effective and technologically advanced architectural design.

We look forward to further collaboration in creating innovative architectural solutions!

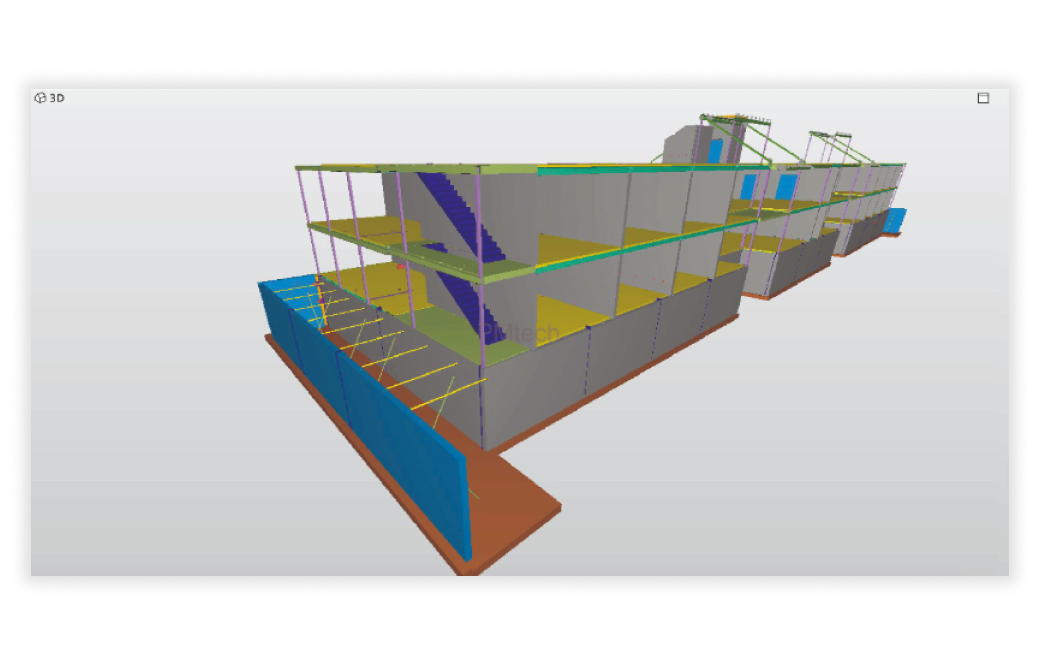

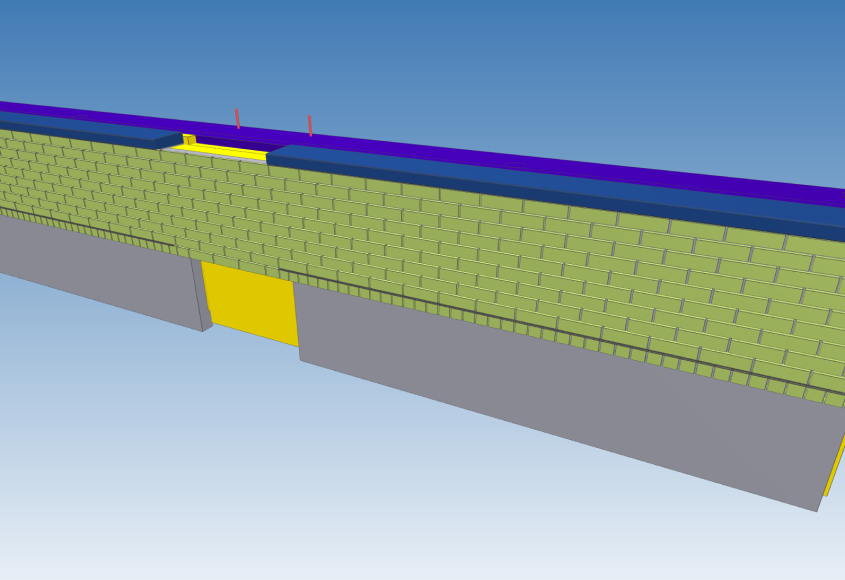

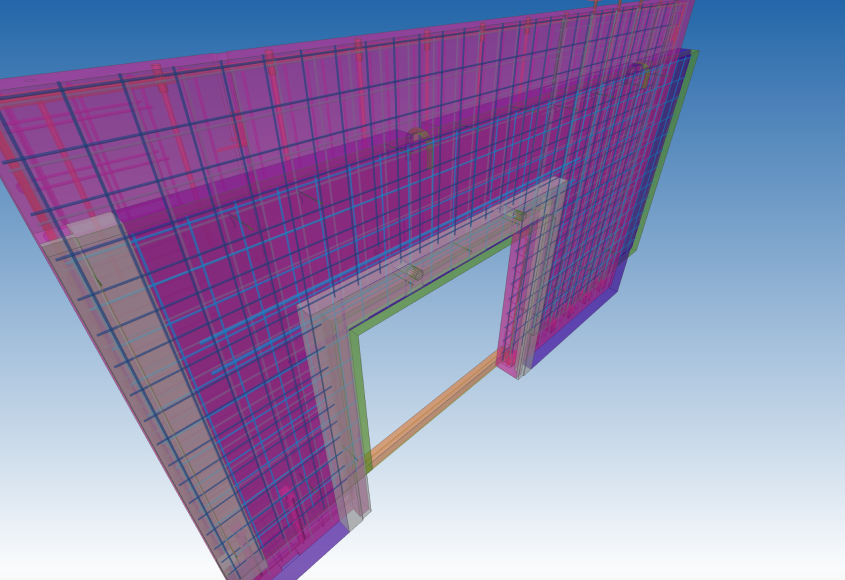

Residential building in Sweden

SOFTWARE PRODUCTS: TEKLA STRUCTURES, DLUBAL RFEM, EXCEL SPREADSHEETS.

PROJECT INFORMATION

Status: Built, 2020-2021

Standards: EUROCODE 0,1,2,3, Sweden NA (EKS11)

This residential building has a total area of ~4500 m2 and consists of cast on site foundation, hollow-core slab, precast internal and external one-layer walls, external three-layer walls, stairs, steel beams, concrete beams. The stability of the building has been provided by concrete walls being fastened together with shear dowels and a seam connection system. Filigree slabs provide a stiff diaphragm, which transfers horizontal loads to concrete walls. Structural robustness is provided by horizontal and vertical ties.

PROJECT DESCRIPTION

Scope of work PMtech Engineering:

– Calculations (load collection, stability calculation, cross-sections and reinforcement, retaining walls);

– Communication with the architect, MEP engineers, precast factory, site team, weekly meetings

– Structures detailing in Tekla Structures (precast concrete)

– Production and installation drawings

– Material lists

Key project features:

– Lintel supports above walls;

– Out-of-plane forces on walls from balconies;

– Edge retaining walls.

Office for 2000 employees. Modern campus.

SOFTWARE PRODUCTS: AUTODESK REVIT, 3D MAX

PROJECT INFORMATION

Architectural features such as triangular, hexagonal and octagonal building shapes required meticulous technical planning. Our technical engineer and architect implemented innovative technologies and solutions to ensure efficiency and comfort in the workplace.

PROJECT DESCRIPTION

Incorporating advanced smart building systems, the engineer automated lighting, heating and air conditioning, as well as security systems using advanced biometric and video surveillance technologies. In line with trends in technical engineering, the concept of a “green” office was introduced, optimizing energy consumption and incorporating renewable energy sources.

“Innovative shapes and glass facades emphasize boldness and modernity, reflecting the company’s philosophy of leadership and creative solutions”.

The primary objective was to create a technologically advanced office space, combining innovation with a high level of comfort for the company’s 2000 employees, a task accomplished by our specialist.

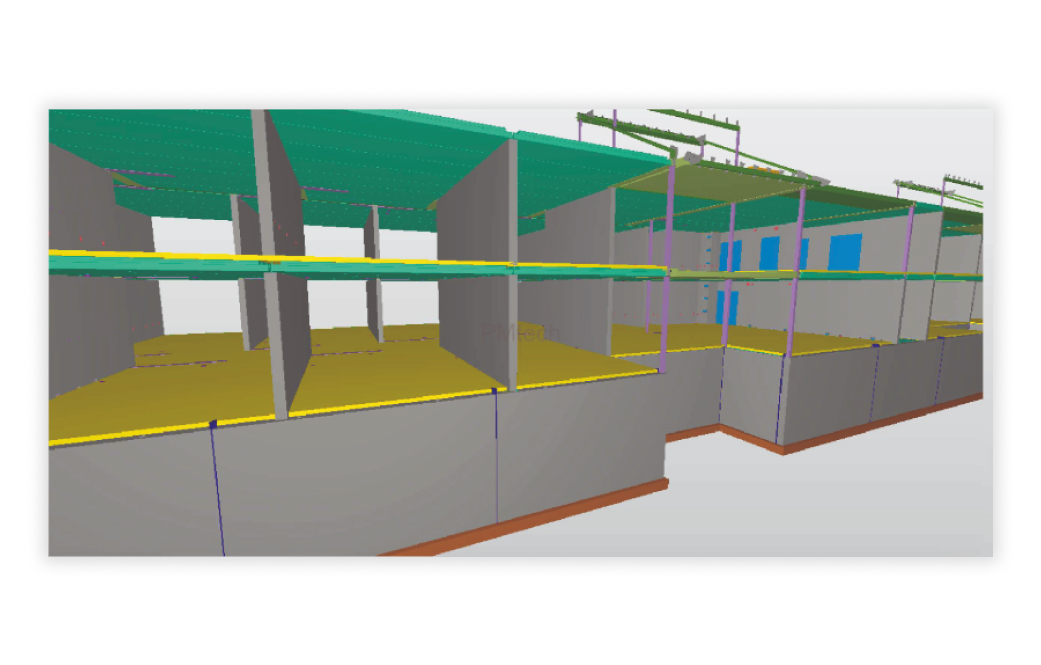

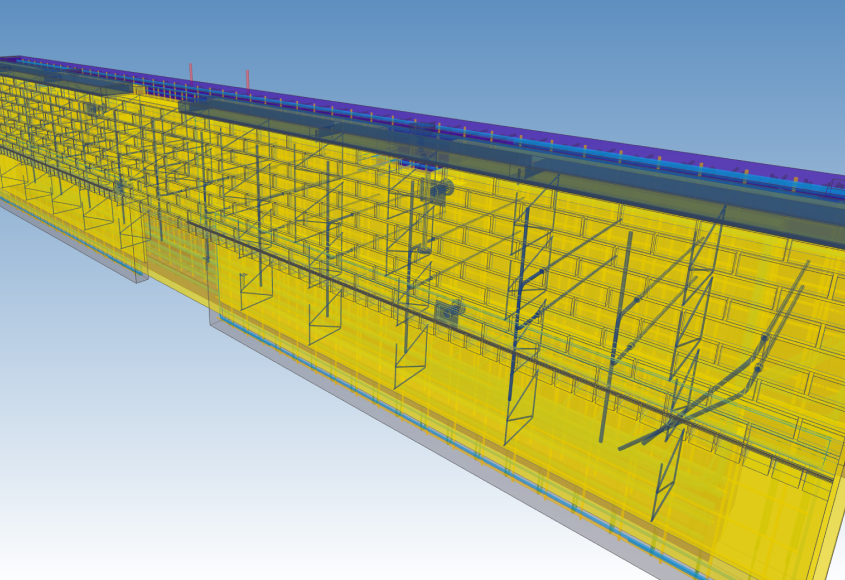

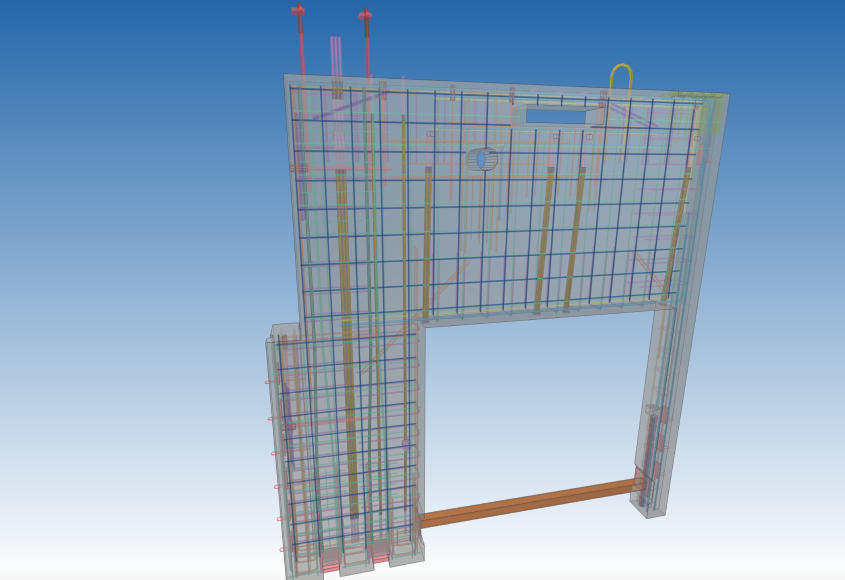

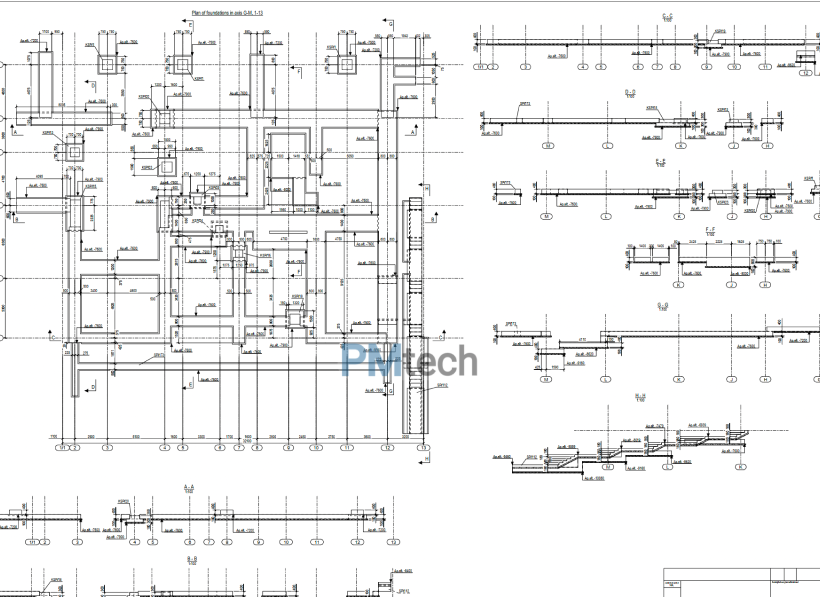

Structural design (precast elements)

SOFTWARE PRODUCTS: TEKLA STRUCTURES, TEKLA MODEL SHARING, DLUBAL RFEM

PROJECT INFORMATION

Commercial spaces.

600-800 precast elements per Project.

PHASE

Technical stage. Detail design.

Precast concrete structural design

PROJECT DESCRIPTION

How do we work with precast concrete manufacturers?

Two types of clients approach our PMtech Engineering company for the design of precast concrete elements:

- Large factories that already have a well-established design-manufacture-delivery environment for precast products using high-precision digital tools;

- Companies that are just switching to the digitalization of their production.

How can we be useful to companies?

PMtech Engineering is fully integrated into your environment and rules. Our engineering team analyzes your design and manufacturing requirements.

In this case, a special guide and instructions for engineers are prepared with the accepted numbering system, reinforcement brands, standards (SS-EN, LT EN, etc.), shapes, diameters, and rules for modeling reinforcement and meshes, lifting and transportation, used hinges, a complete range of products and materials needed for production.

Depending on the platform on which the customer’s internal environment is built: it can be Tekla Structures with Trimble Connect (or a SharePoint project) or Autodesk Revit with BIM360, the initial conditions are agreed. Further development is carried out in a single environment with the customer and his engineering team. This approach allows information to be tracked to reduce guesswork and data loss. For precast or cast-in-place concrete contractors, this means reduced risk and rework throughout the life of the project, and the opportunity to significantly increase productivity in the office and in the field with better, more coordinated, and more timely information.

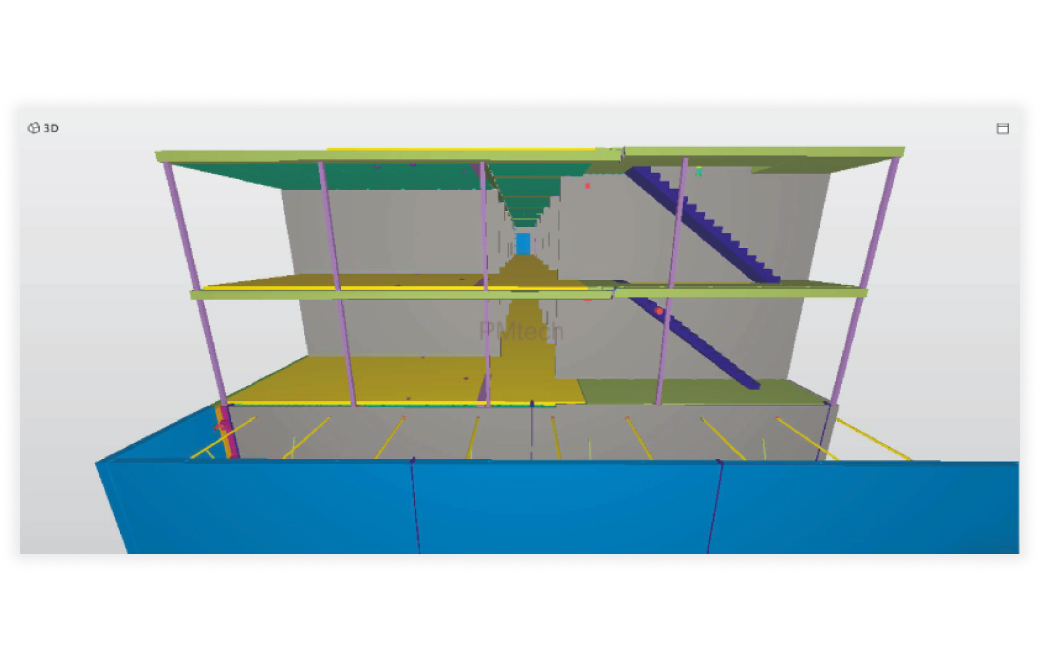

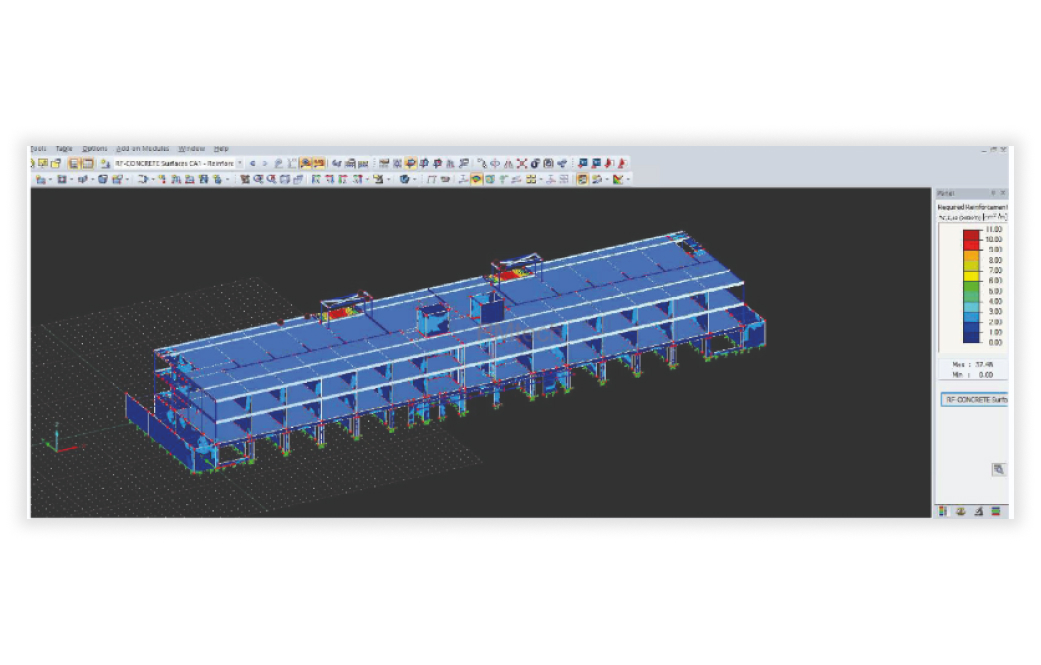

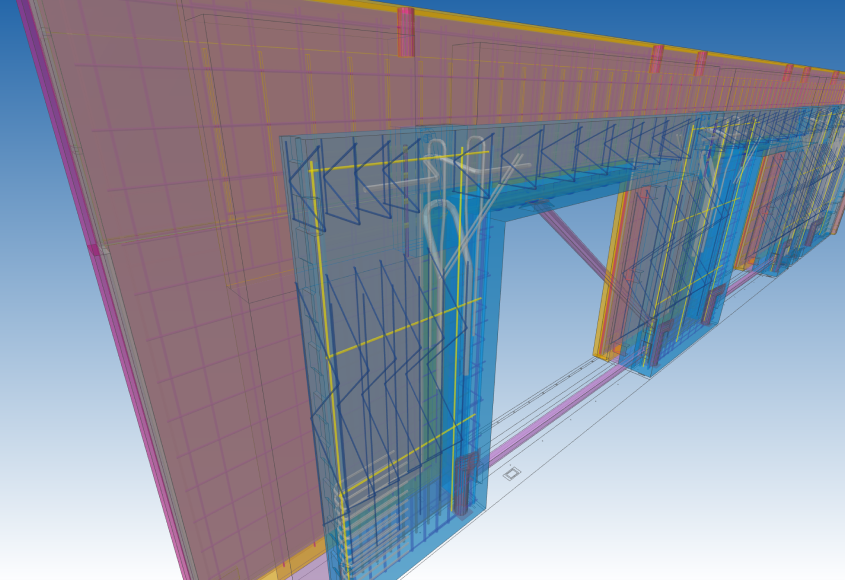

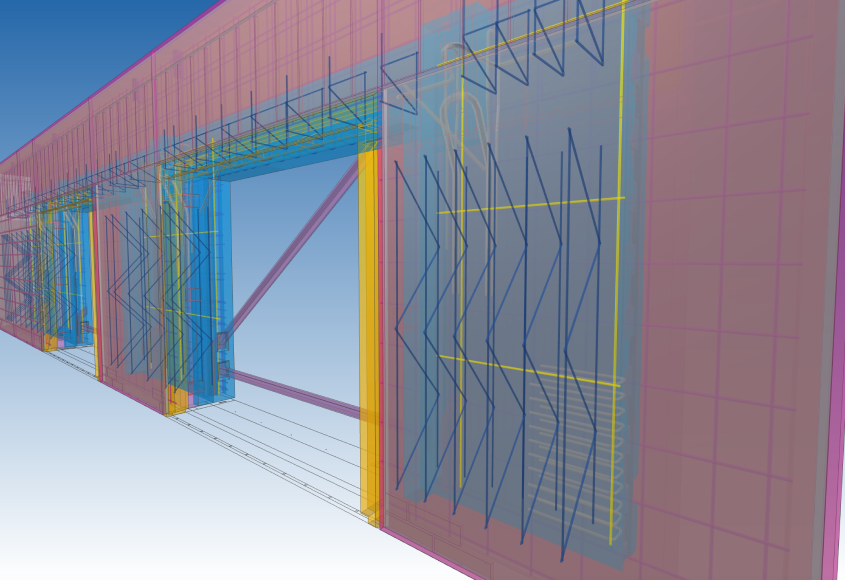

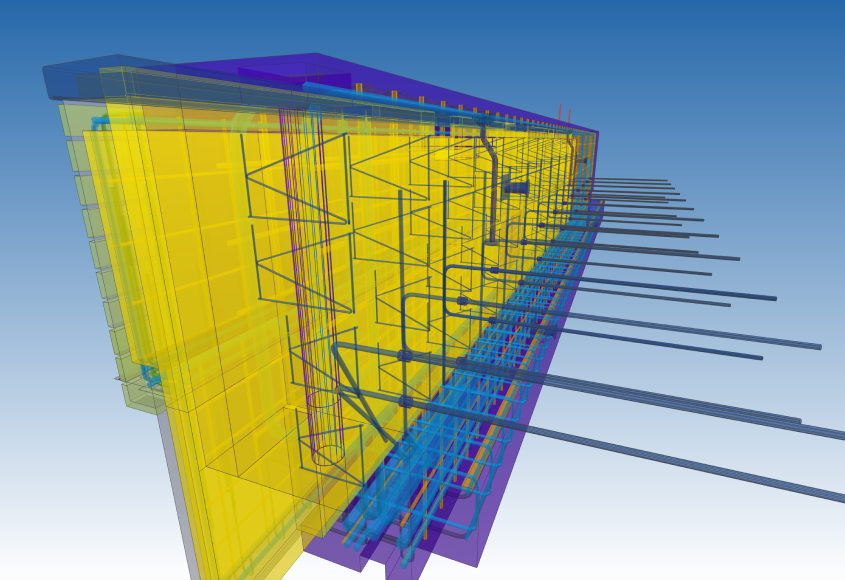

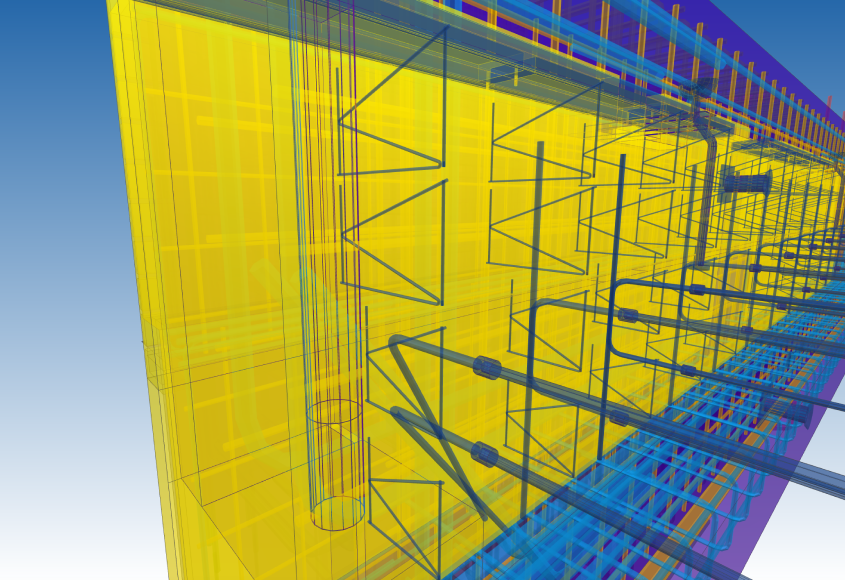

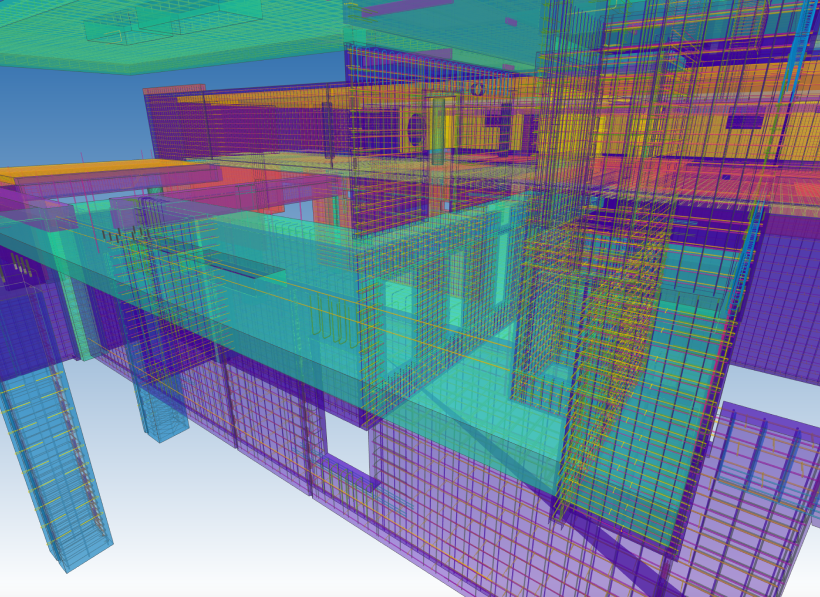

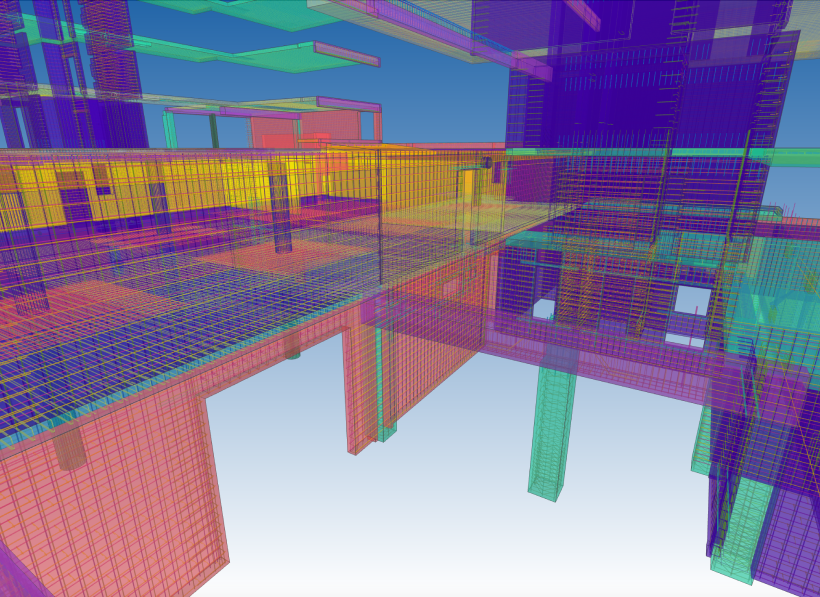

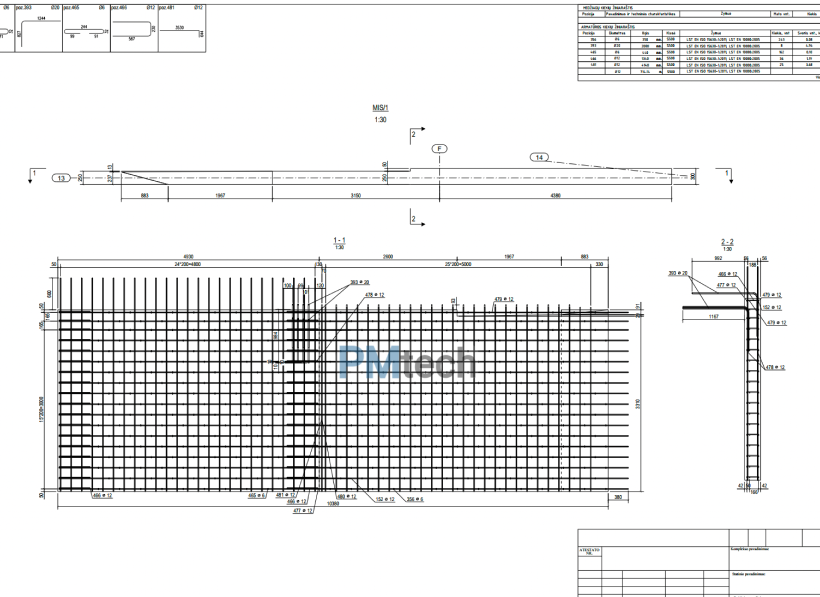

3D rebar detailing in the cast-in-situ projects

SOFTWARE PRODUCTS: TEKLA STRUCTURES, TEKLA MODEL SHARING, DLUBAL RFEM

PROJECT INFORMATION

Precast and cast-in-place concrete house projects are implemented using Tekla Structures as the design tool.

Our experienced 3D rebar detailers provide efficient reinforcement modeling in 3D to help contractors achieve construction-ready level of accuracy (LOD400) and information rich detailed rebar design and documents for high-rise buildings, schools, residential and social facility. Transferring data to production teams and exchanging information amongst project stakeholders, ultimately resulting in savings across the cast-in-place concrete project lifecycle.

Through the use of Tekla Structures, we were able to study the 3D model in detail and review both the potential advantages and constructability of changing the concrete design.

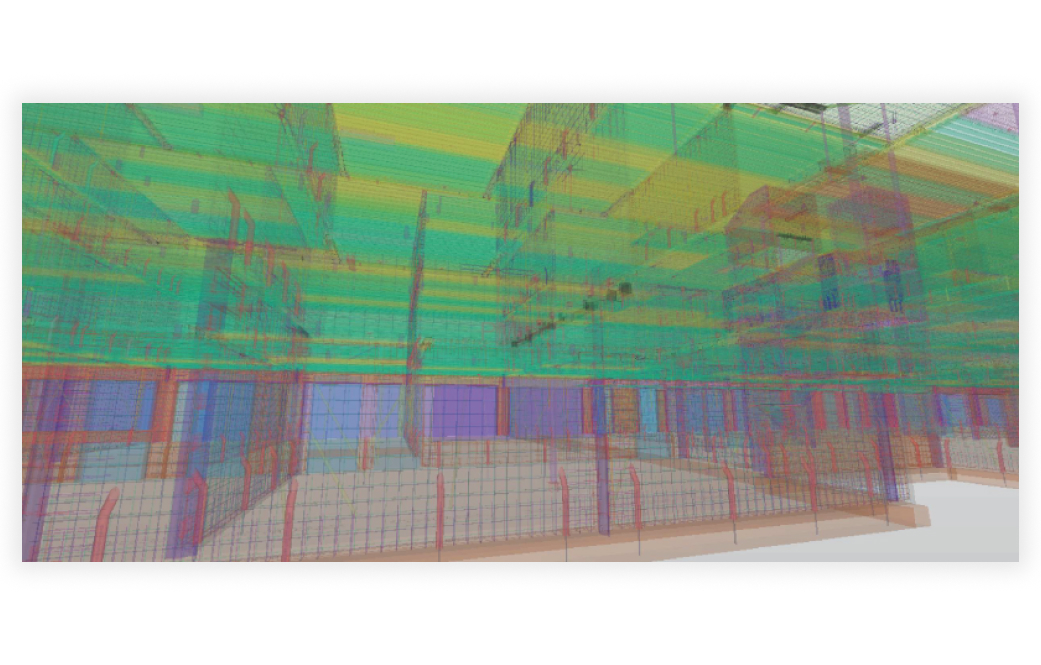

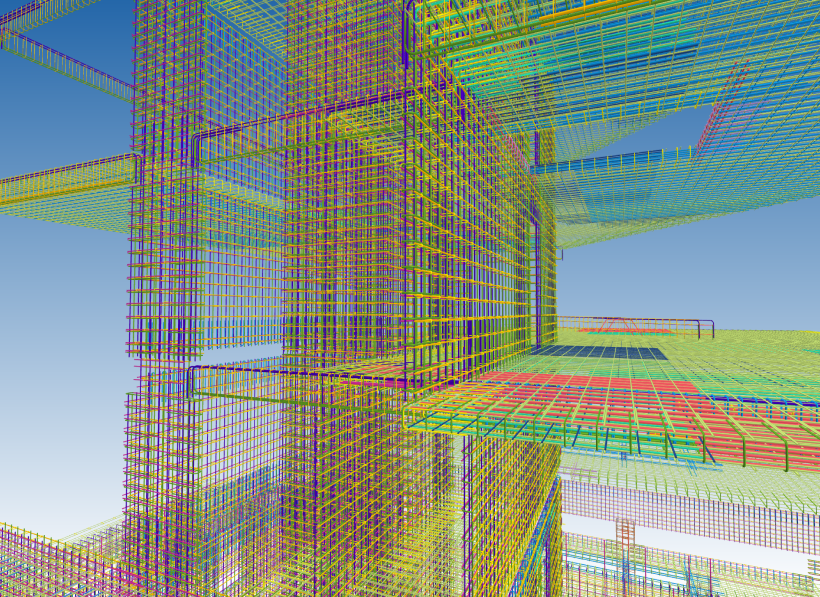

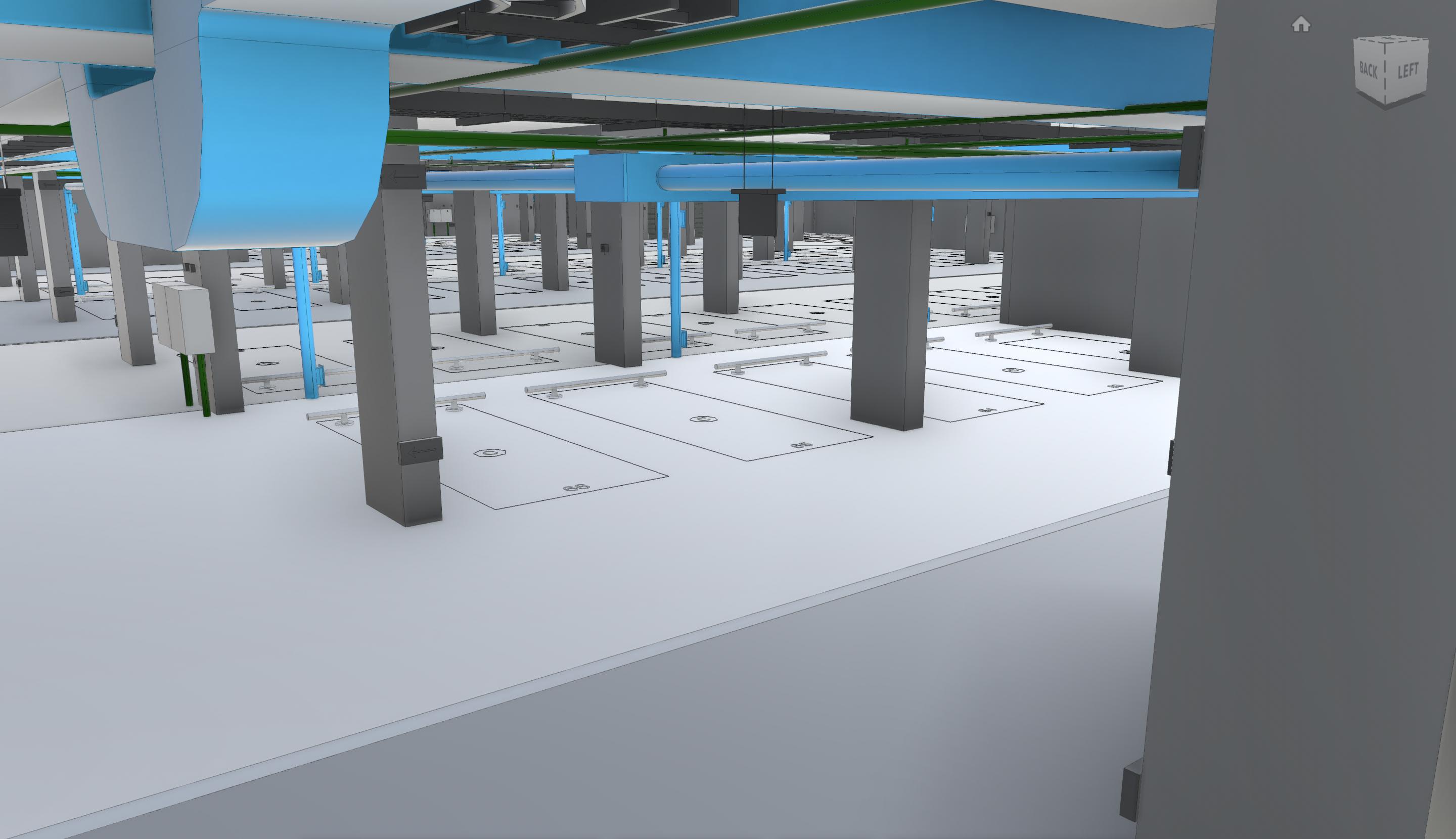

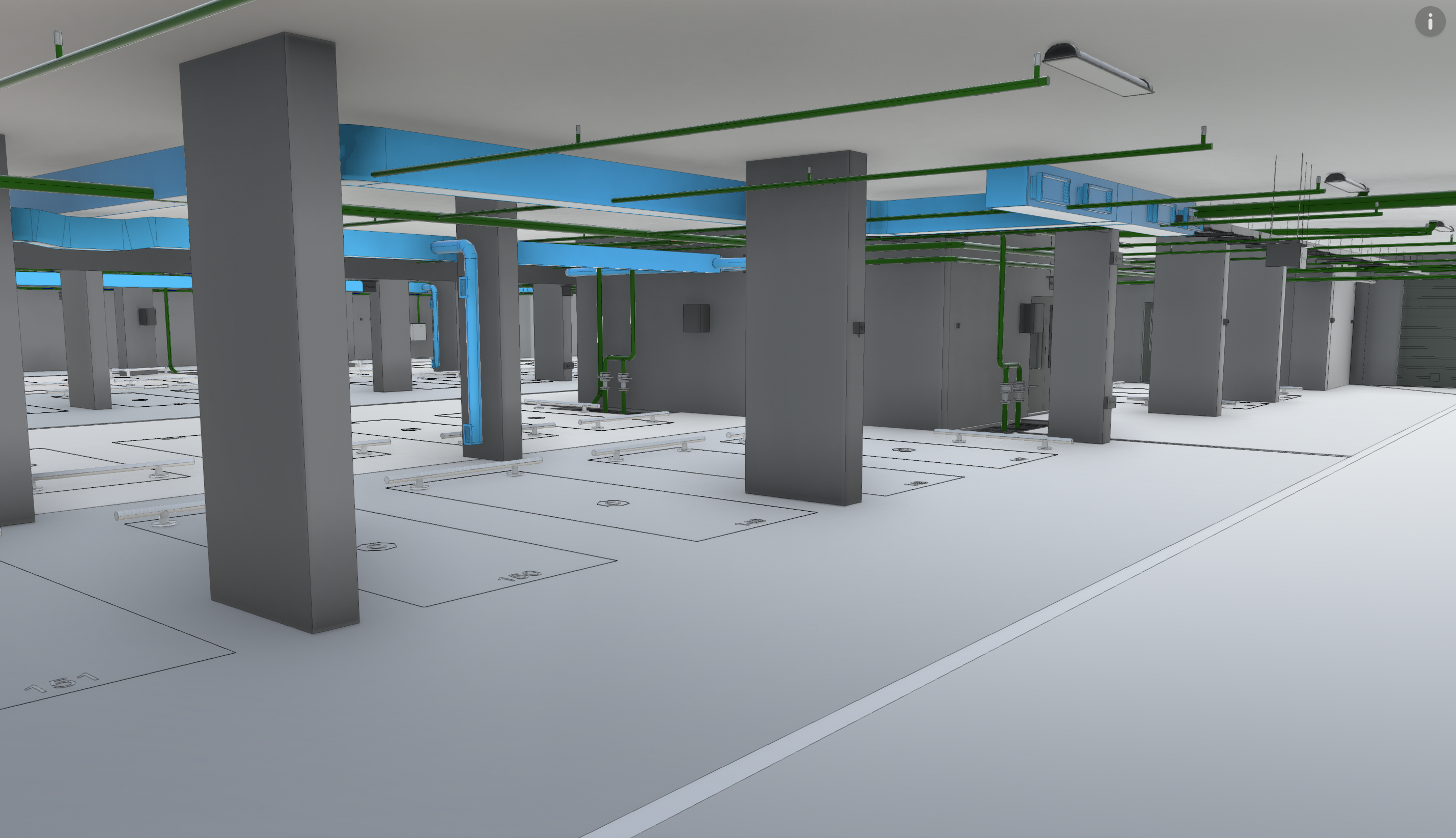

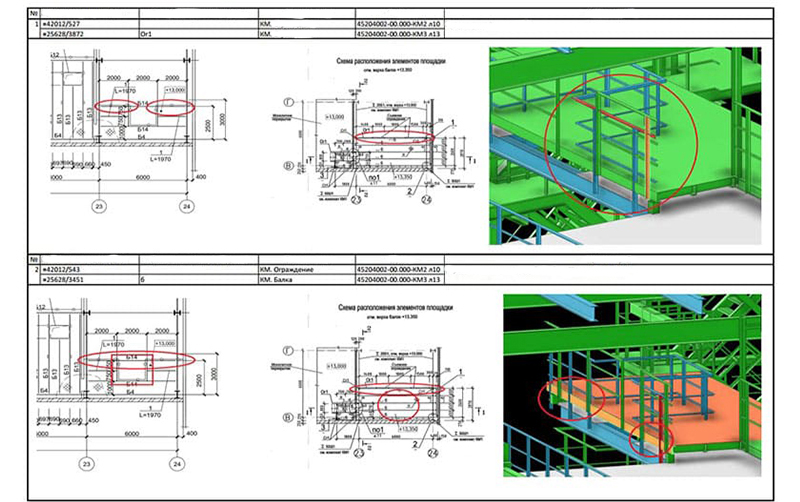

3D model checking and control for clashes

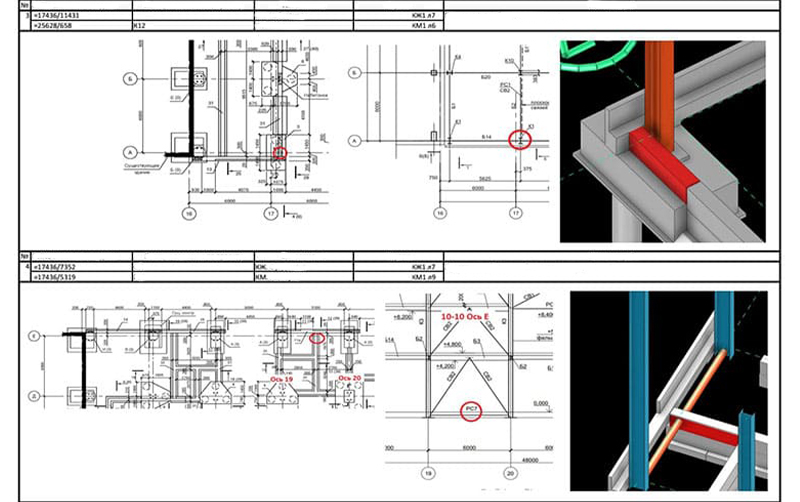

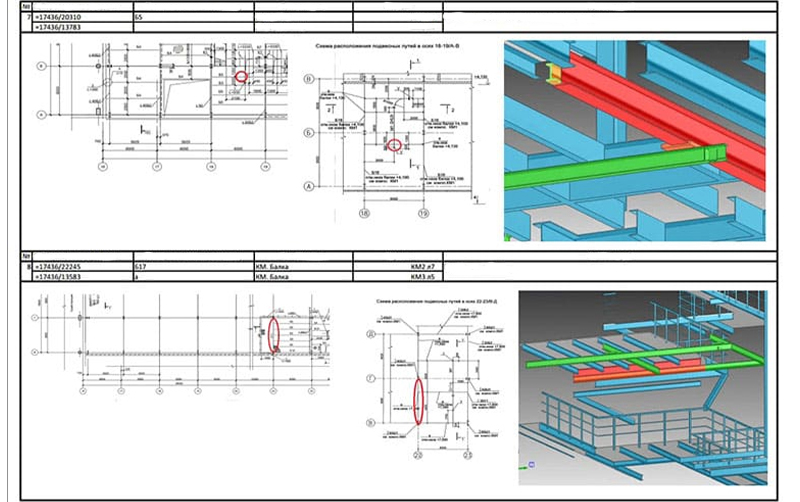

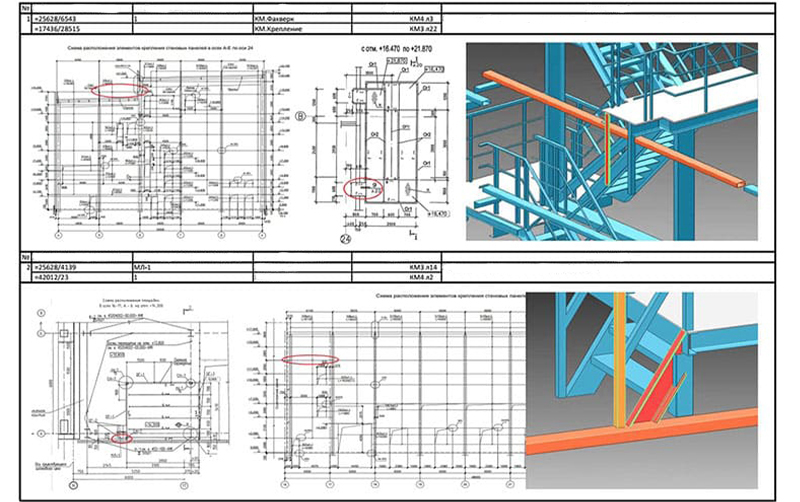

Applying a “clash-free” BIM design is possible in very rare situations.

We were wondering about the required and adequate accuracy level of quality assurance in 3D model checking and control for clashes especially when it comes to its application in the real-life environment, at the construction phase for example. In most cases, the BIM model is handed over with several clashes when the site work is almost completed. The model must ensure no complex critical clashes occur in the multidisciplinary environment on the construction site.

The occurrence of minor clashes is not excluded in the BIM model. It may depend on some factors including initial software settings, numerous planning changes on the client-side, delays in the schedule, and decisions to be made yet.

PMtech supposes the success of the BIM case can be analyzed and assessed in the context of the whole project and a host of factors including less obvious and even deferred ones sometimes. We will be pleased to demonstrate a full version of the VDC BIM control and tell you about our capabilities in case of interest.

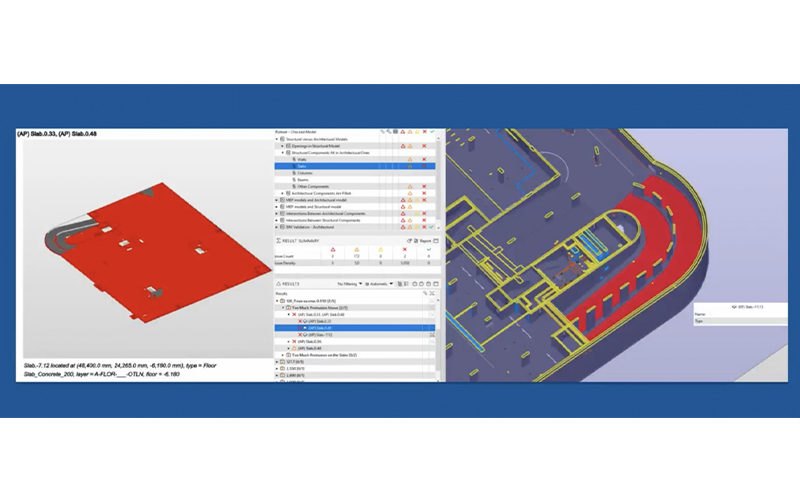

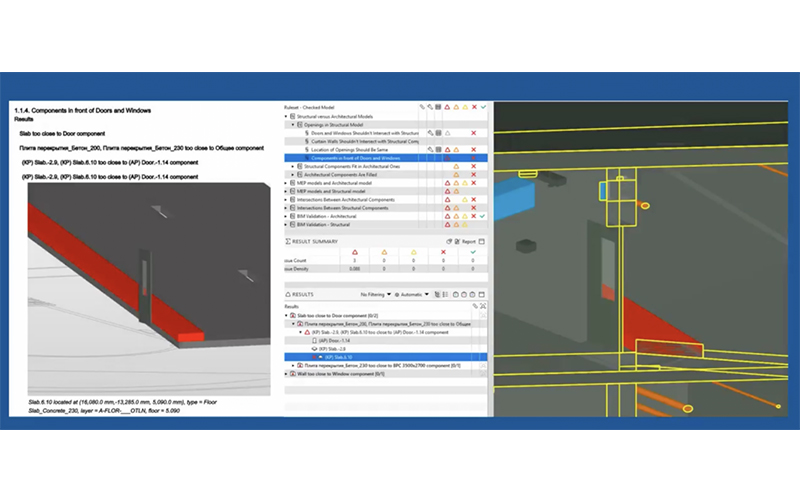

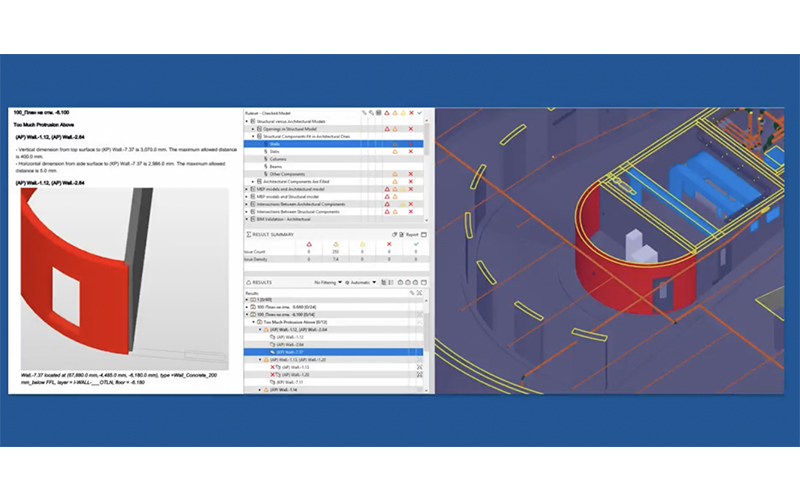

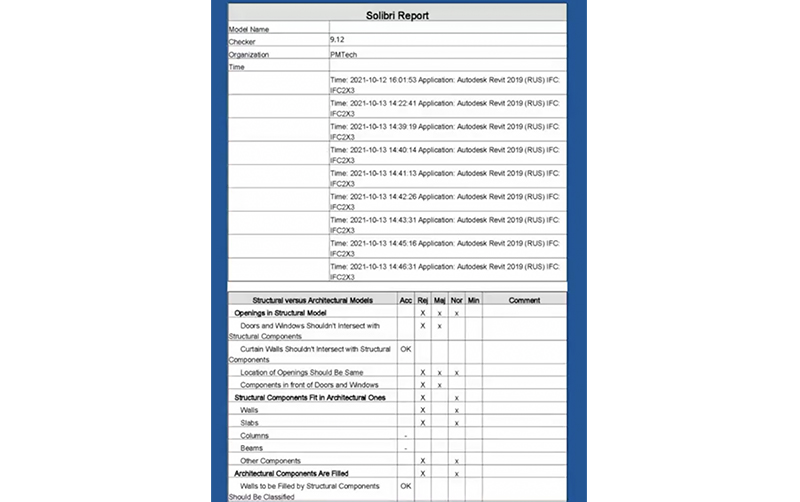

The clash detection checking of the model was performed (Solibri software)

– based on an object – underground parking (as a part of a residential complex that includes reinforced cast-in-situ structures, 22 floors);

– scope of work contained;

– checking for clashes;

– data analysis and reports review.

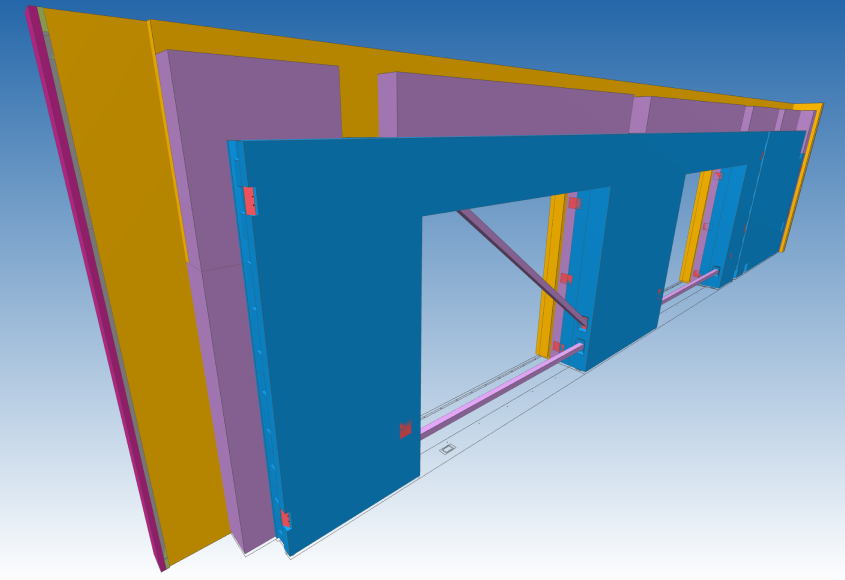

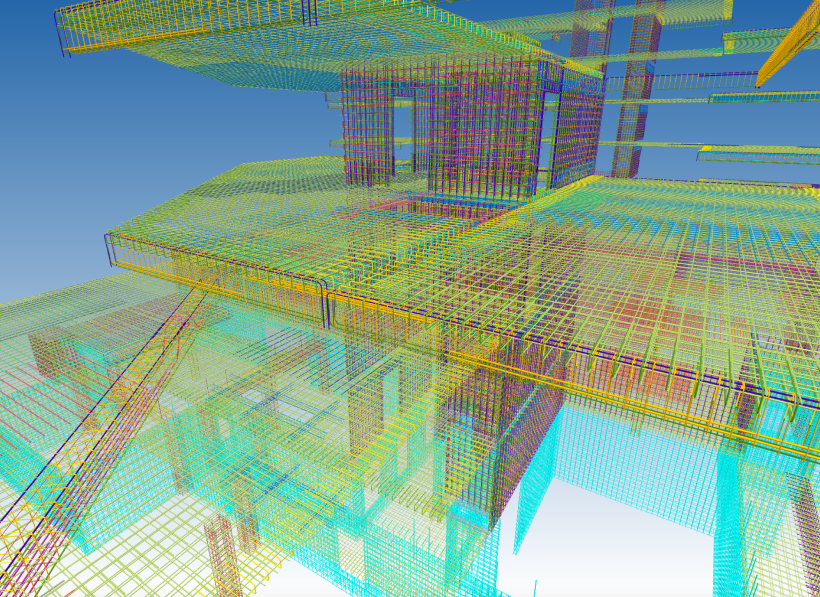

Clash detection in 3D models

SOFTWARE PRODUCTS: AUTODESK REVIT, AUTODESK NAVISWORKS, SOLIBRI TOOLS

PROJECT INFORMATION

All Digital Twins projects

PHASE

Basic design stage. Detailed design stage.

Renovation. Construction (support stage).

PROJECT DESCRIPTION

Clashes (intersections between objects or elements) result in costly time delays and material costs. They can be found on the construction site when correction is impossible or partially possible, but the best solution is to find intersections at the design stage and at an early stage. PMtech Engineering – highly experienced BIM team, that provides BIM project management services for the Scandinavian region.

There are several methods in the BIM strategy for finding clashes we use.

● BIM expertise, BIM consultancy: The first one is through the automatic model checking that allows us to detect most physical collisions and thereby save time for the construction planning with BIM requirement preparation (Navisworks, Solibri Model Checker).

● BIM coordination: In the process of algorithmic rules and manual verification by a specialist, intellectual collisions are revealed that have not been noticed by specialized programs and can only be detected based on the logic and experience of the employee.