Designing Cross-Laminated Timber (CLT) structures

Jul 22, 2024

Posted by Maria Begouleva

Designing timber and Cross-Laminated Timber (CLT) structures at the tender stage involves several crucial steps to ensure a successful and efficient construction process.

Firstly, understanding the structural capabilities and limitations of timber and CLT is essential. Timber and CLT have unique properties and design considerations compared to traditional building materials like steel and concrete. They require a thorough understanding of how loads are transferred, moisture and fire resistance, and detailing for connections.

During the tender stage, it’s important to collaborate closely with architects, structural engineers, and suppliers to ensure that the design is practical, cost-effective, and meets all the necessary legal and safety requirements. This includes selecting the appropriate timber or CLT grades and sizes, specifying connection details, and considering any specific project requirements or constraints.

Furthermore, at the tender stage, it’s important to pay attention to the overall project timeline and sequencing. Timber and CLT construction may have different lead times and installation requirements compared to traditional materials, so this needs to be factored into the construction schedule.

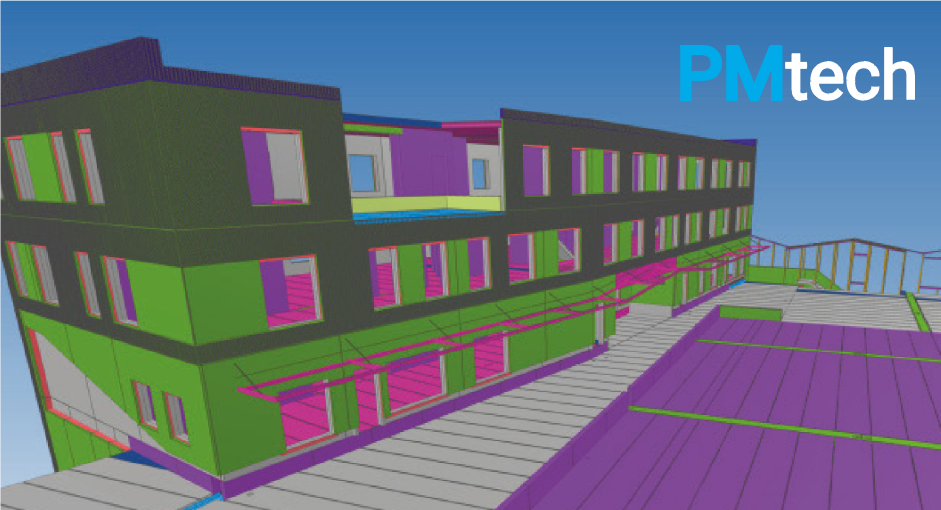

Additionally, with the increasing use of prefabrication and modular construction in timber and CLT projects, digital tools can play a significant role in optimizing design, coordination, and fabrication processes. As a structural engineering company, we’ve found that this stage could greatly benefit from the use of Building Information Modeling (BIM) software (CadWorks, Tekla Structures, Revit Autodesk). BIM allows for 3D visualization and simulation of the timber and CLT structures, aiding in clash detection, quantity takeoffs, and construction sequencing.

We encourage you to find out more about DfMA, CLT and timber designs in contemporary architectural styles.

Discover the power of timber engineering at the upcoming conference on May 29th: The online conference about DfMA from Ergodomus Timber Engineering company https://lnkd.in/dYevnkqZ

Maria Begouleva

Director of Engineering (CTO), PMtech Group

PMtech Engineering can generate CNC data to control automated machinery for fabrication directly from the 3D model Tekla Structures.

June 23, 2023

CNC (Computer Numerical Control) is a method of automated equipment control used in manufacturing, including milling machines, lathes, laser cutters, and other types of machines.

PMtech Engineering’s scope of work with digital building design. Level 1.

June 21, 2023

Generate output lists by providing intelligent attributes along with 3D information.

Generate quantity lists and bills of materials for all elements.Determine space states.

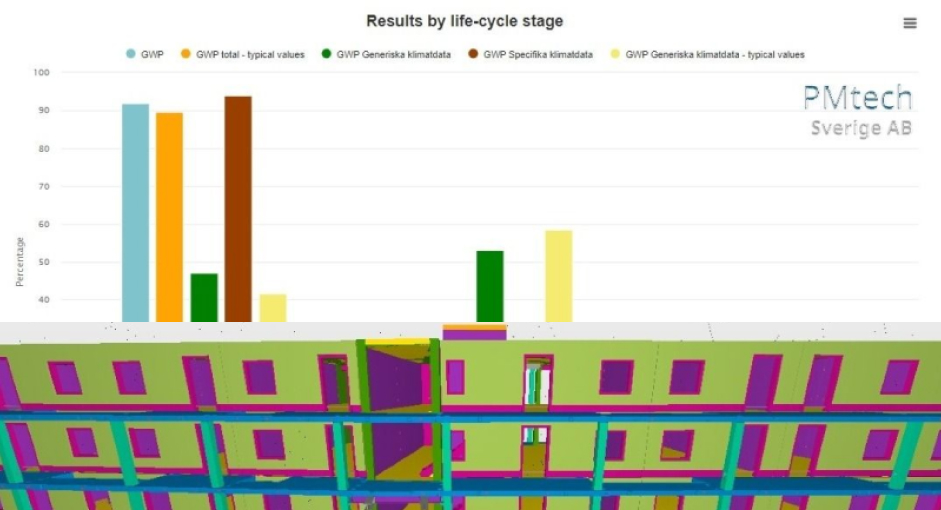

CO2-optimization of reinforced concrete frames by simulated annealing

June 6, 2023

In our projects, we are strongly committed to the values of sustainable development and environmental policy in all our projects. From early-stage consultations to CO2 optimization.