Shop Drawings vs General Arrangement (GA) Drawings

Jul 7, 2023

Posted by Maria Begouleva

Understanding the differences

As an engineer working in the field of steel detailing, it is essential to understand the disparities between shop drawings and general arrangement (GA) drawings. While both play significant roles in the construction process, they serve distinct purposes and provide unique information.

Let’s delve into these differences:

1️⃣ Shop Drawings (WSD)

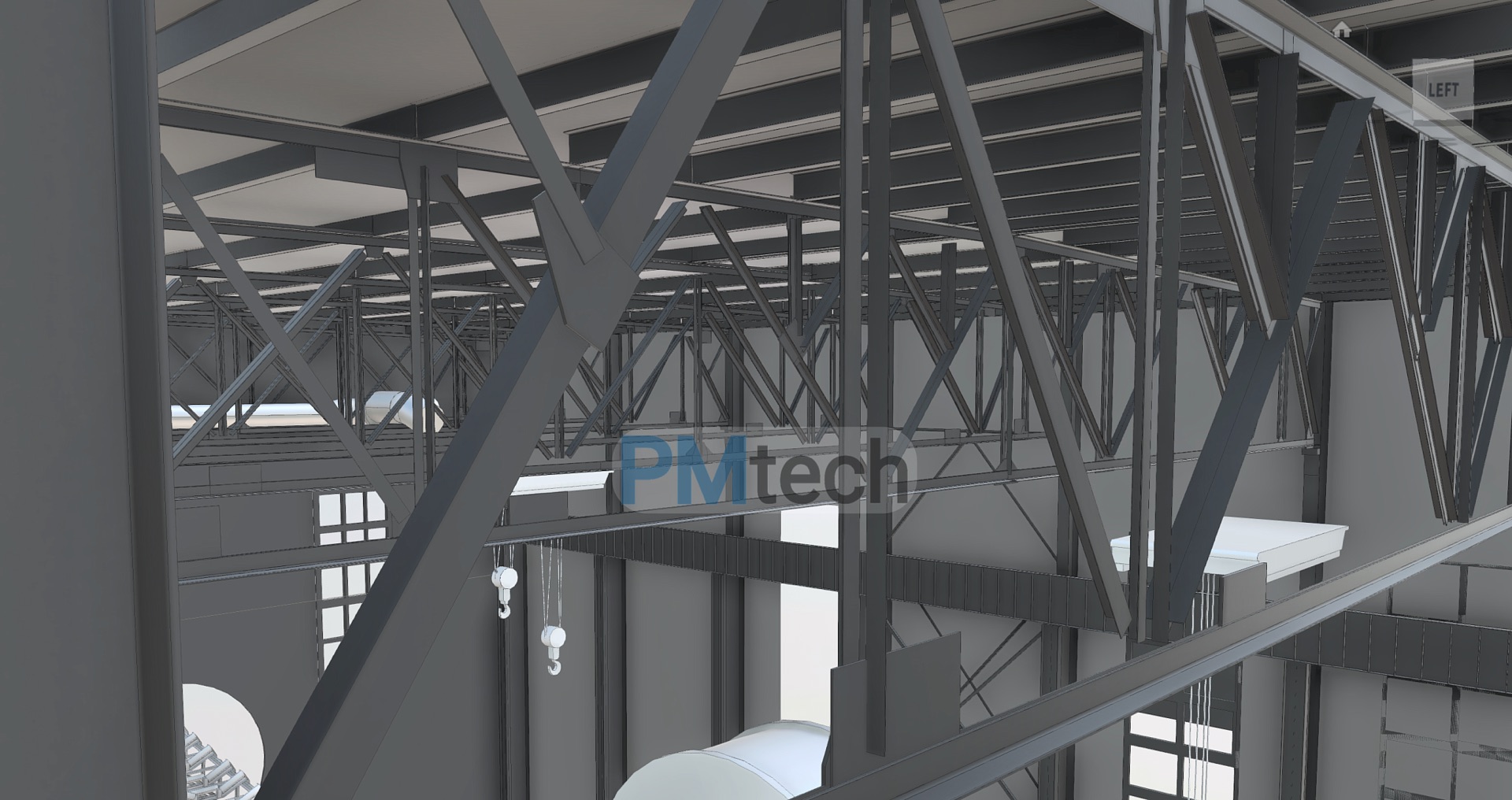

Shop drawings, created by professionals like PMtech Engineering, serve as a guide for steel fabricators during the assembly of the structure. These drawings contain detailed information on how the steel components should be fabricated and installed.

They provide instructions related to the manufacturing process, including welding points, connection details, and specific dimensions. Shop drawings act as a bridge between the design intent and the physical realization of the structure.

2️⃣ General Arrangement (GA) Drawings

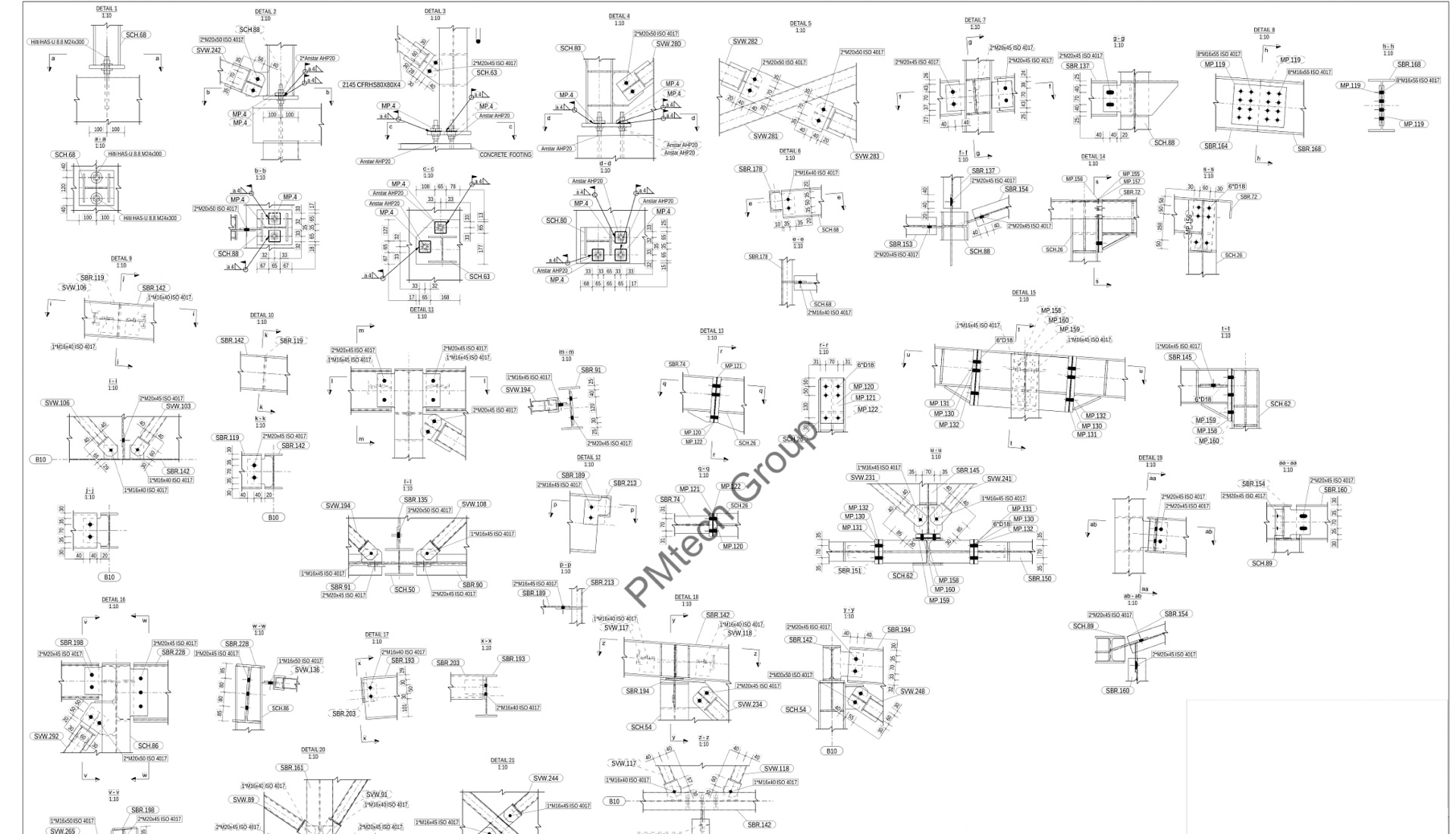

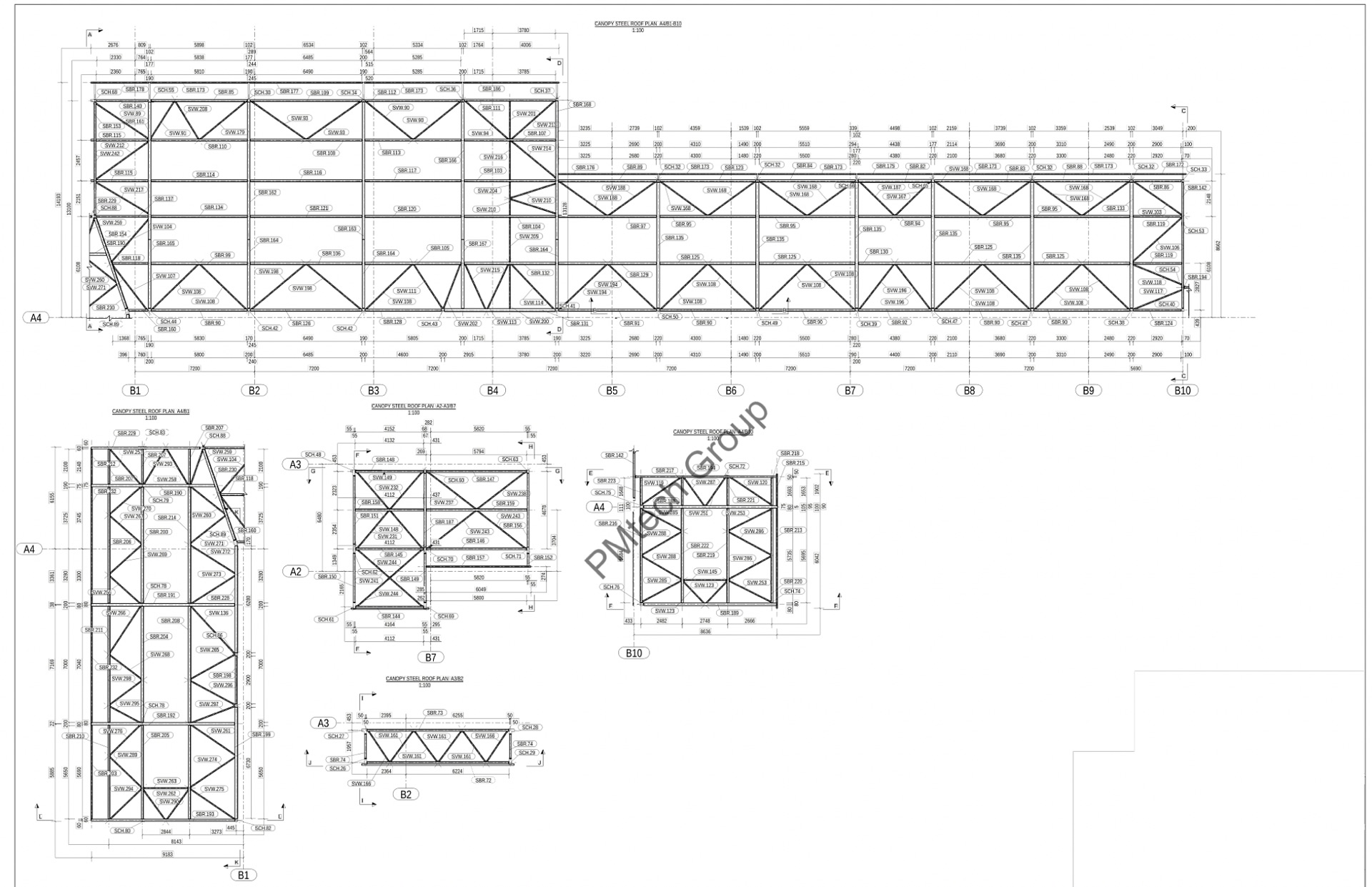

In contrast, GA drawings delve even deeper into the construction process. They provide comprehensive and precise instructions for constructing each individual element of the steel structure.

Fabrication drawings specify exact dimensions, material specifications, welding symbols, and other necessary details required for the manufacturing process. Steel fabricators utilize GA drawings to ensure accuracy and adherence to design specifications during the production of steel components.

In summary, the key difference between shop drawings and GA drawings lies in their level of detail and purpose.

Shop drawings primarily focus on guiding fabricators during the assembly process, while GA drawings provide specific information needed for manufacturing each component.

Together, these drawings ensure the seamless translation of the design concept into a tangible steel structure.

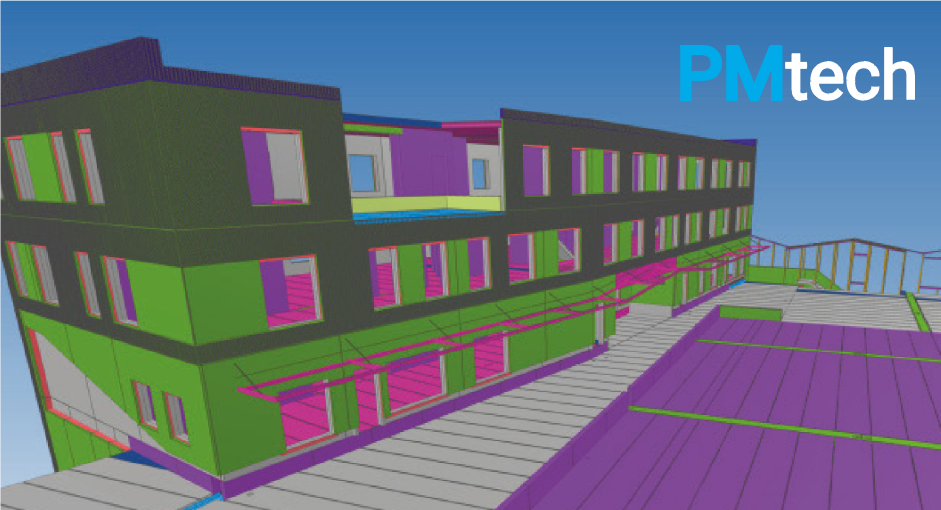

By utilizing advanced software such as Tekla Structures, structural engineers can efficiently generate both shop drawings and GA drawings.

This technology reduces lead times, minimizes errors, and enhances communication among project team members. Accurate and detailed drawings streamline the steel fabrication process, ultimately resulting in a high-quality final product.

For engineers, mastering the nuances between shop drawings and GA drawings is crucial for effective collaboration with fabricators, ensuring the successful realization of the steel structure in accordance with design intent.

Maria Begouleva

Director of Engineering (CTO), PMtech Group

PMtech Engineering can generate CNC data to control automated machinery for fabrication directly from the 3D model Tekla Structures.

June 23, 2023

CNC (Computer Numerical Control) is a method of automated equipment control used in manufacturing, including milling machines, lathes, laser cutters, and other types of machines.

PMtech Engineering’s scope of work with digital building design. Level 1.

June 21, 2023

Generate output lists by providing intelligent attributes along with 3D information.

Generate quantity lists and bills of materials for all elements.Determine space states.

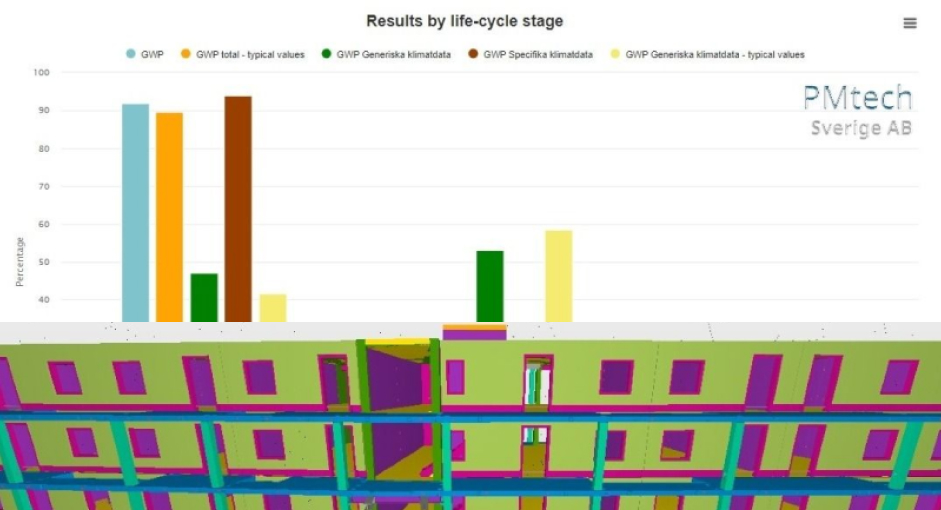

CO2-optimization of reinforced concrete frames by simulated annealing

June 6, 2023

In our projects we are strongly committed to the values of sustainable development and environmental policy in all our projects. From early stage consultations to CO2 optimization.