Why do we detail in 3D?

Jul 12, 2024

Posted by Maria Begouleva

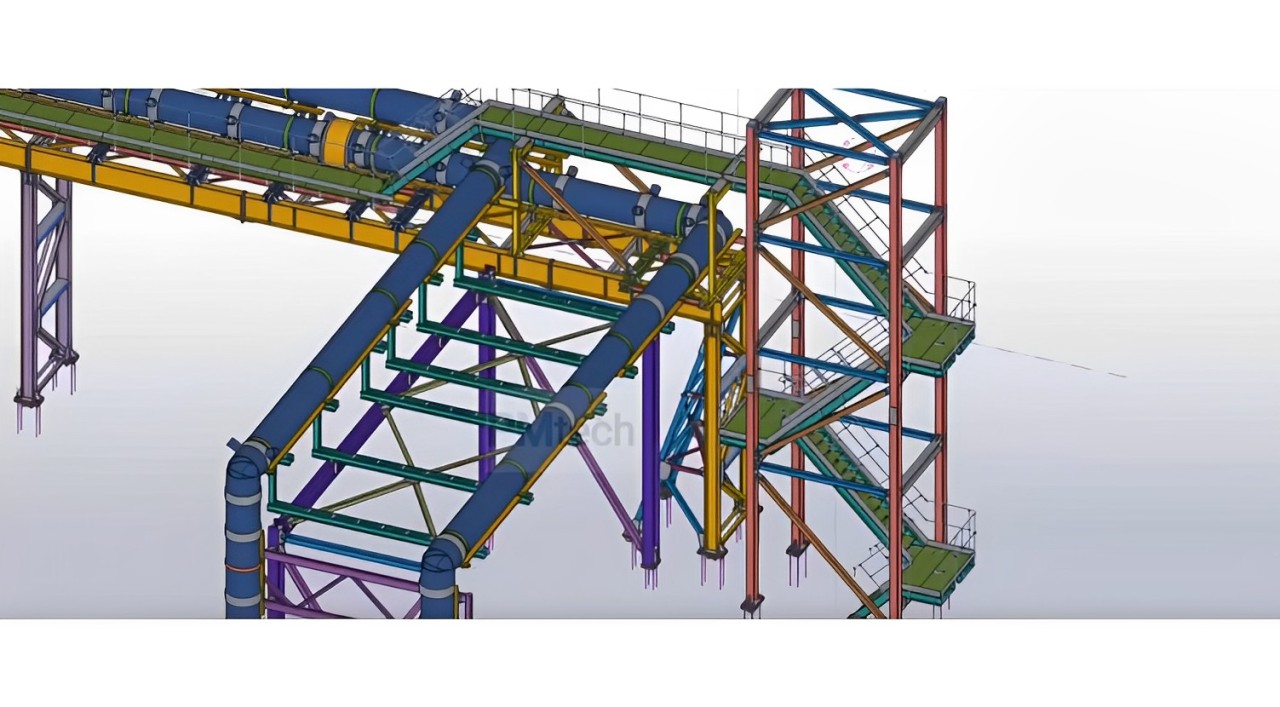

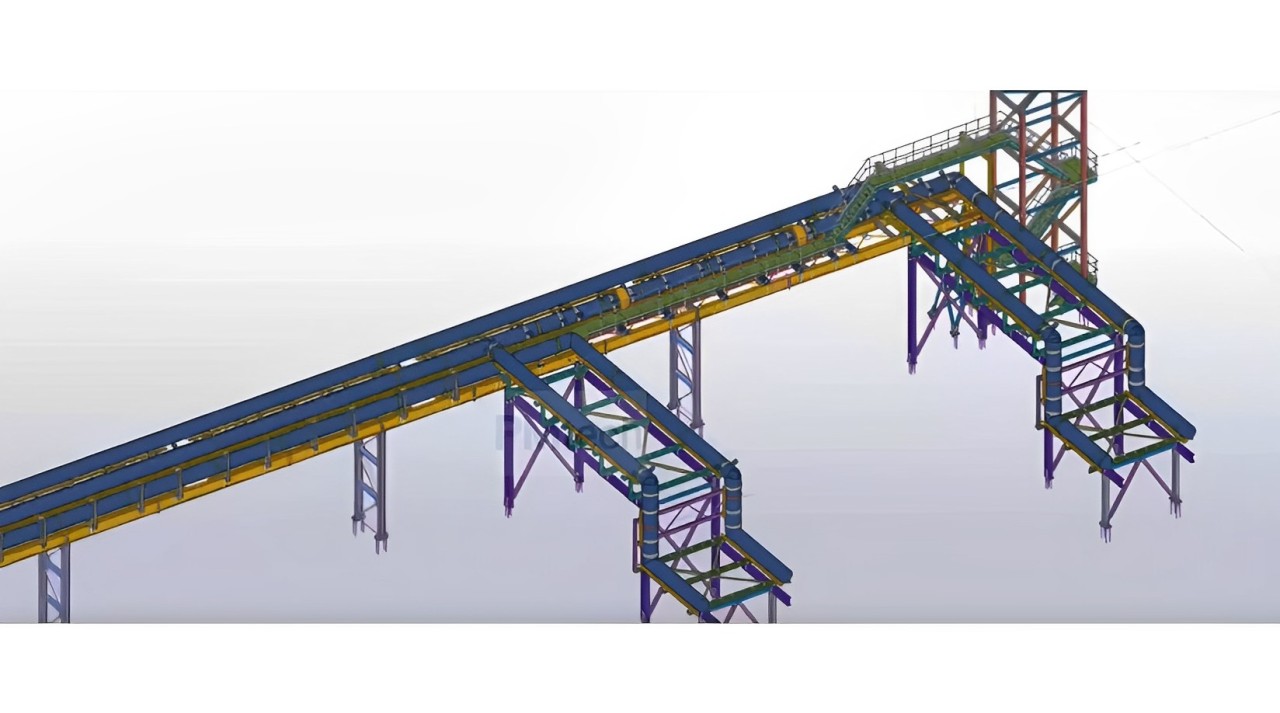

3D steel detailing offers numerous advantages over traditional 2D methods:

- Enhanced Visualization: With 3D modeling, stakeholders can visualize the steel structure in a realistic, immersive environment before construction begins. This allows for better decision-making, early detection of clashes or design flaws, and improved communication among project teams.

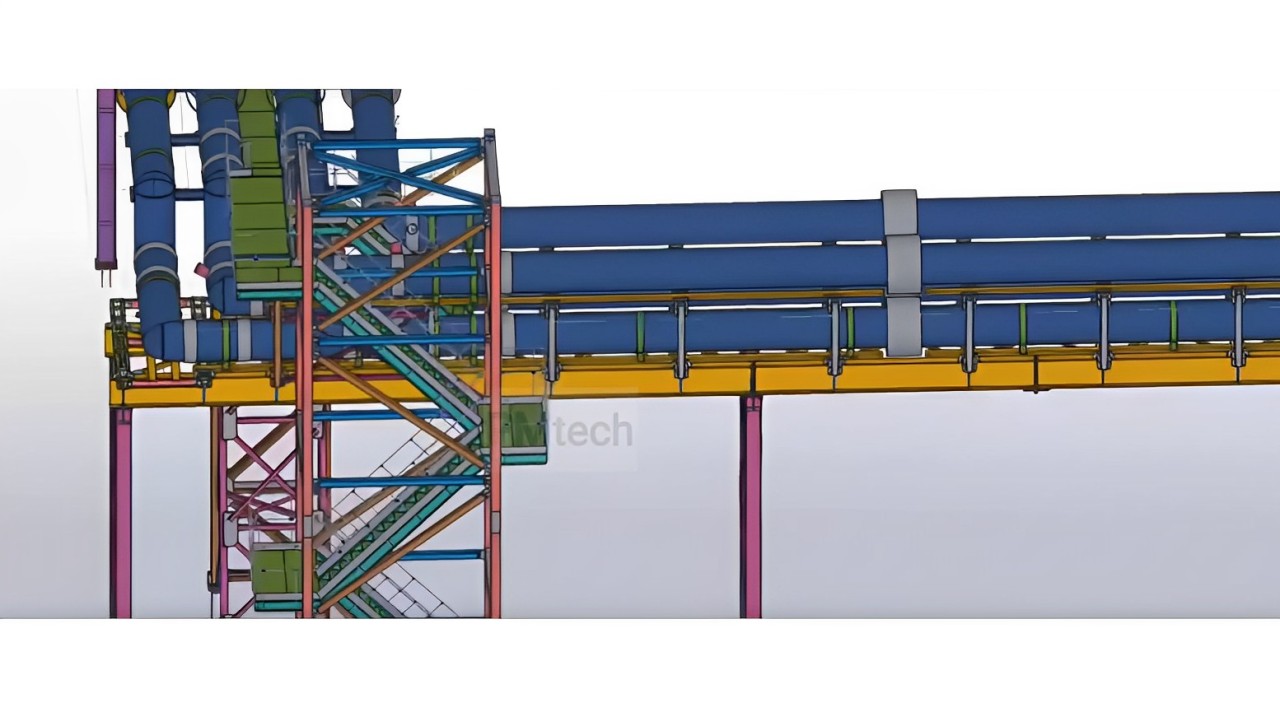

- Accurate Representation: 3D models provide a more accurate representation of the final structure compared to 2D drawings. This accuracy minimizes errors and reduces the need for costly revisions during the construction phase, ultimately saving time and money.

- Clash Detection: 3D models enable clash detection, allowing designers to identify and resolve clashes between steel elements, mechanical systems, and other building components before they become costly issues on-site. This proactive approach enhances coordination and minimizes rework.

- Improved Coordination: 3D models facilitate better coordination among architects, engineers, steel fabricators, and contractors by providing a centralized platform for collaboration. This ensures that everyone is working from the same information, leading to smoother project execution.

- Streamlined Fabrication: 3D models can be directly utilized for steel fabrication, eliminating the need to interpret 2D drawings and reducing fabrication errors. This seamless transition from design to fabrication improves efficiency and accelerates the construction timeline.

- Quantity Takeoffs: 3D models enable accurate quantity takeoffs, allowing project stakeholders to estimate material quantities more precisely. This helps in procurement planning, cost estimation, and resource allocation, leading to better project budgeting and management.

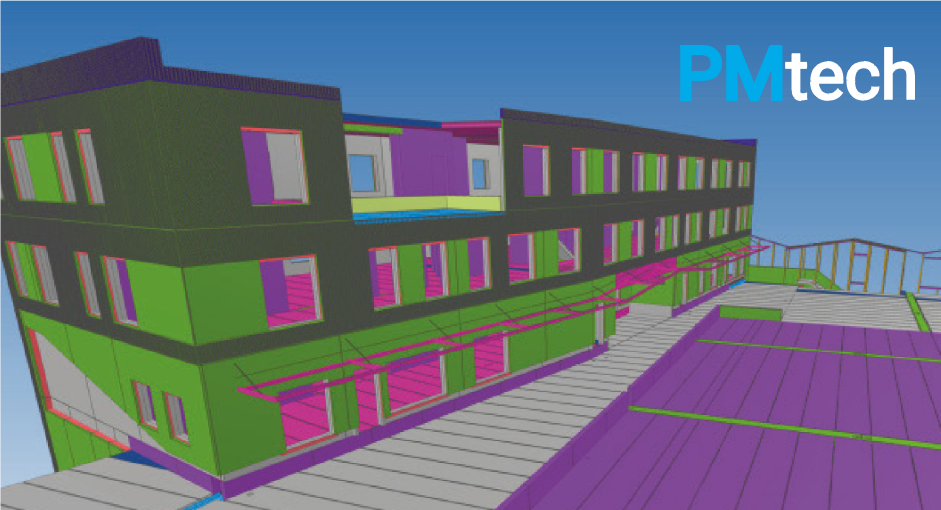

- Enhanced Presentation: 3D models can be rendered with high-quality visualizations and animations, making them ideal for client presentations, marketing materials, and stakeholder engagement. This helps convey the project’s vision and potential more effectively, fostering client satisfaction and buy-in.

Whether you are embarking on a new construction project or seeking to enhance an existing structure, trust our PMtech Engineering team to deliver 3D steel solutions (Tekla Structures, Advance Steel, Revit Autodesk) that exceed your expectations.

Get in touch with us today to learn more about how our steel detailing services can help you achieve your project goals.

Maria Begouleva

Director of Engineering (CTO), PMtech Group

PMtech Engineering can generate CNC data to control automated machinery for fabrication directly from the 3D model Tekla Structures

June 23, 2023

CNC (Computer Numerical Control) is a method of automated equipment control used in manufacturing, including milling machines, lathes, laser cutters, and other types of machines.

PMtech Engineering’s scope of work with digital building design

June 21, 2023

Generate output lists by providing intelligent attributes along with 3D information.

Generate quantity lists and bills of materials for all elements.Determine space states.

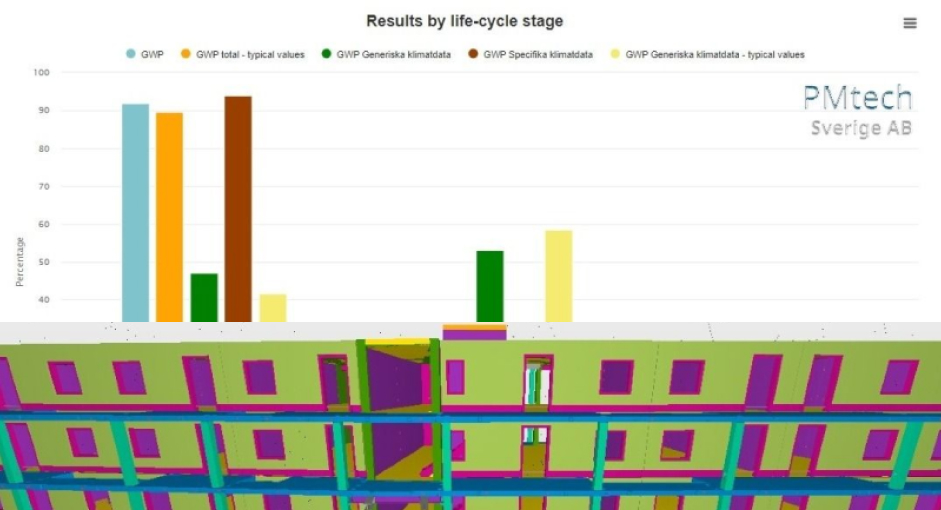

Optimisation of reinforced concrete for CO2 emissions

June 6, 2023

In our projects we are strongly committed to the values of sustainable development and environmental policy in all our projects. From early stage consultations to CO2 optimization.